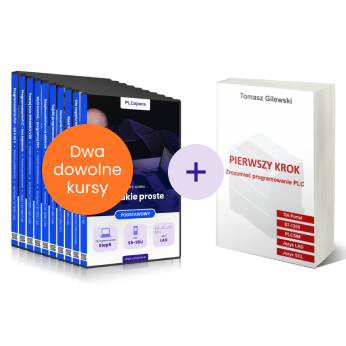

Create your own package

Select at least 2 courses and an automatic discount of 25% will be calculated in your shopping basket.

Dodatkowo w ramach BONUSU otrzymasz książkę „Pierwszy krok – Zrozumieć programowanie PLC” GRATIS!”

Dodatkowo w ramach BONUSU otrzymasz książkę „Pierwszy krok – Zrozumieć programowanie PLC” GRATIS!”

[ywfbt_form product_id=""].

By ordering a minimum of two products in a bundle, you will not only receive a discount of 25%,

ale również w prezencie książka „Pierwszy krok – Zrozumieć programowanie PLC”

ale również w prezencie książka „Pierwszy krok – Zrozumieć programowanie PLC”

Duration

25h

Format

Flash drive, DVD, Online

Shipping EN

For free

Shipping abroad

Available

VAT invoice

Yes

Proforma order

Yes

Online delivery

Immediately