Programming in FBD for novices

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

49.00 zł – 99.00 zł

What will you gain from enrolling in the FBD Programming for Beginners course?

You don't have to worry about being inundated with complex knowledge that is difficult to learn. Our SIMATIC S7-1200 PLC programming course in FBD language is designed to introduce you to the basics of programming industrial equipment. Its main aim is to provide a solid foundation and introduce you to the essential skills needed to work with PLCs. As part of the training you will receive:

A novel approach to programming in FBD for beginners.

Are you wondering if PLC programming is for you? Have you never had to deal with programming industrial equipment? If so, you've come to the right place! This intro course is specifically designed for beginners. You will learn about Siemens' most popular controller, the SIMATIC S7-1200.

What can you expect from the course "Programming in FBD for novices" for Siemens SIMATIC S7-1200 PLC logic controllers?

Our course will provide you with a comprehensive explanation of automation topics and PLC programming in FBD language. We will make use of the popular SIMATIC S7-1200 series controller and the TIA Portal programming environment. You will learn how to properly connect electrical equipment and install the necessary software. You will be introduced to the basics of PLC programming, where you will make practical use of fundamental programming instructions. This course will provide you with the necessary knowledge in industrial automation.

Knowledge test:

Is this course for you? Take this test MULTIPLE choice to check it out.

Important information about the course

As you go through the practical exercises, you will see that programming is not as difficult as it may seem.

While attending the training course, you will be introduced to the interesting world of the industry and gain relevant information related to the field.

You will enhance your skills with guidance from experienced developers.

In the course you will learn how to use the tool to configure the PLC, create programme code and program the device. At the end you will see the results of your work.

You get a comprehensive source of information, which saves time and avoids making basic mistakes in action.

Why choose to take the course?

You will find a wealth of information on PLCs and programming on the internet.This course is distinguished by its proprietary method, developed from years of experience working with beginners. The lessons have been carefully arranged in a logical sequence that provides practical knowledge, eliminating excess theory. Want to find out what you will learn in this course? Below are the main elements of the programme.

Example lesson from the course

How is the course in FBD programming going?

The most important information is that you have the opportunity to do the exercises yourself on your own computer. The course has been designed with everyone in mind, regardless of knowledge level. We start with the basics, which are essential for understanding the subject. On the basis of these basics, a variety of tasks are presented, together with an explanation of their solution. In addition, you will find exercises in the course that encourage you to solve the problems yourself.

The Siemens Simatic S7-1200 PLC programming course consists of modules, each of which is a separate thematic section. You will find detailed information on each topic covered in the training course. The table of contents is carefully designed so that you can easily navigate through the course and consciously select topics of interest.

Lista modułów szkolenia

Software and hardware used

CPU S7-1200

The new controller, which has been developed as a successor to the S7-200, is characterised by slightly weaker parameters than the S7-300 family. Several CPU versions present in the family allow selection according to project requirements.

TIA Portal software

Totally integrated automation is a development environment that combines PLC (programming), HMI(visualisation) and startdrive(drive technology).

What jobs will you be able to work in after completing your training?

Completing this course 'Programming in FBD for novices' will help you to achieve your professional goals by enhancing your skills in PLC programming. Gaining knowledge of programming is the first step to taking up a position in industrial automation.

Bear in mind that just learning and going through this course is only the beginning. For this course, our main focus is on the practical application of elementary knowledge of PLC programming. This will enable you to master practical skills more quickly, just by taking the time to absorb the material and practise on your own. It is through practice that you will consolidate the knowledge you have acquired and become confident in programming the SIMATIC S7-1200 PLC in FBD language. Our aim is for you not only to understand the theory, but also to be able to apply it effectively in practice. Therefore, we encourage you to actively participate in the course and practice regularly, which will help you achieve better results and become a confident and competent PLC programmer.

Guarantee

and certificate

If, after 14 days of purchase, you find that it is not for you, I will refund 100% of the course price. Upon completion of the course, you will receive a certificate in two languages - Polish and English.

Frequently asked questions

-

Do I need to have some basic knowledge of programming and PLC?

No. It's all in the course. We start from scratch.

-

Is it worth starting to learn with a Siemens PLC?

Yes. Siemens PLCs are in about 95% factories in Poland. The situation is similar in Europe. It is useful to have at least a general idea of this hardware and programming environment.

-

How long will I have access to the course?

Indefinitely.

-

Does enrolling in a course commit you to anything?

No. It is voluntary and at 100% for 0 PLN. It is possible to cancel at any time.

-

Is it worth learning PLC programming?

Everything nowadays lives up to automation to increase productivity and repeatability. Companies want to produce for 24 hours. You need machines and process lines to do all this. Someone has to program this, so you need PLC programmers. If you want to become a PLC programmer, this course would be a good way to start.

-

Why have I created a free course on PLC programming?

I think that anyone in the automation/electrical/mechanical field as well as pupils and students in these technical fields should familiarise themselves with this subject. Then you will be able to say whether this is for me. Whether I like it.

-

Who is this course for?

For people WITHOUT programming experience. For people who have no experience with Siemens PLCs. For all those who want to go step by step through the steps involved in the first commissioning of what is now the most popular PLC of the SIMATIC S7-1200 family.

Buy as a set and save

Select at least 2 courses from the list and the first free book item (three selections in total) and an automatic discount of 25% will be calculated in your basket.

If you want to find out more about a particular course, click on its name and the page will take you to its offerings.

Companies that have benefited from our courses

Feedback from students

Stanislaw

Stanislaw

What sets this course apart is the opportunity to acquire practical, concrete knowledge. Everything is clearly explained. Definitely recommended!

Marcel

Marcel

After going through the course, I know what the components of the programming environment are and what to do step by step. Now I feel confident and know what I am doing

Leon

Leon

Course delivered in a very accessible way. Contains a lot of interesting and useful information.

Michael

Michael

I can honestly recommend the course. It is solid and factual knowledge. I will definitely be buying more.

Victor

Victor

Thanks to the course, I have decided to go further in this direction. The goal is to look for a more challenging and better job

Peter

Peter

The course prepared by Mr Tomasz is distinguished by its high level of content and meticulously prepared lessons. They are planned in a clear and sensible manner, making it easier to assimilate knowledge and return to the material if necessary. An additional advantage is the possibility of a free consultation.

Nikodem

Nikodem

Definitely recommended! The facts themselves, no unnecessary dwelling on issues.

Ignatius

Ignatius

This is my first course, certainly not my last. I am impressed with the substantive quality of the knowledge.

Tymon

Tymon

Everything clearly explained, you can really learn a lot. Lots of practical information and examples to help you remember everything. In my opinion, it is worth using this form of learning because you can learn anytime and anywhere. It is practical and convenient.

You may also be interested in:

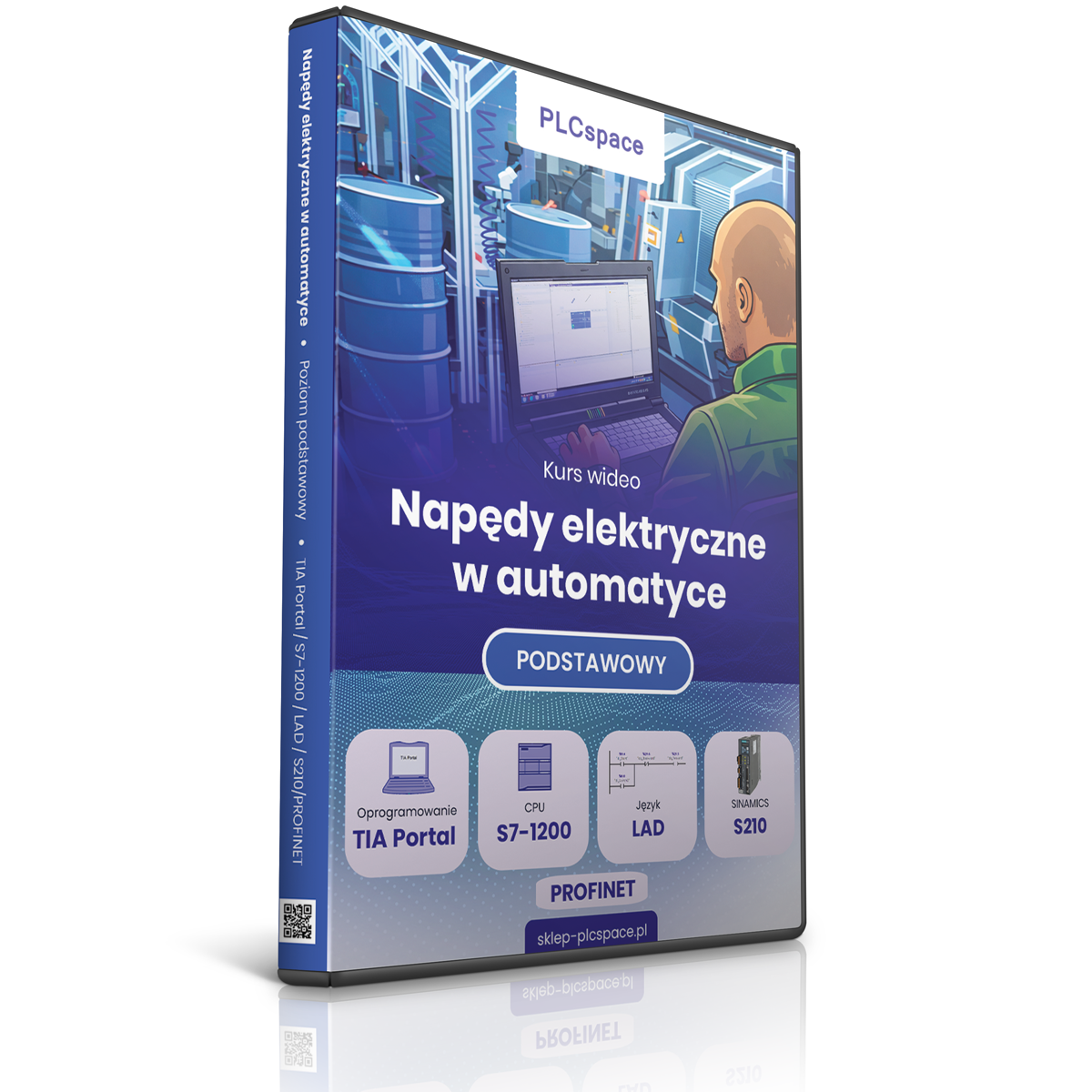

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

979.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

499.00 zł Pierwotna cena wynosiła: 499.00 zł.199.00 złAktualna cena wynosi: 199.00 zł.

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

499.00 zł Pierwotna cena wynosiła: 499.00 zł.199.00 złAktualna cena wynosi: 199.00 zł.

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

499.00 zł Pierwotna cena wynosiła: 499.00 zł.199.00 złAktualna cena wynosi: 199.00 zł.