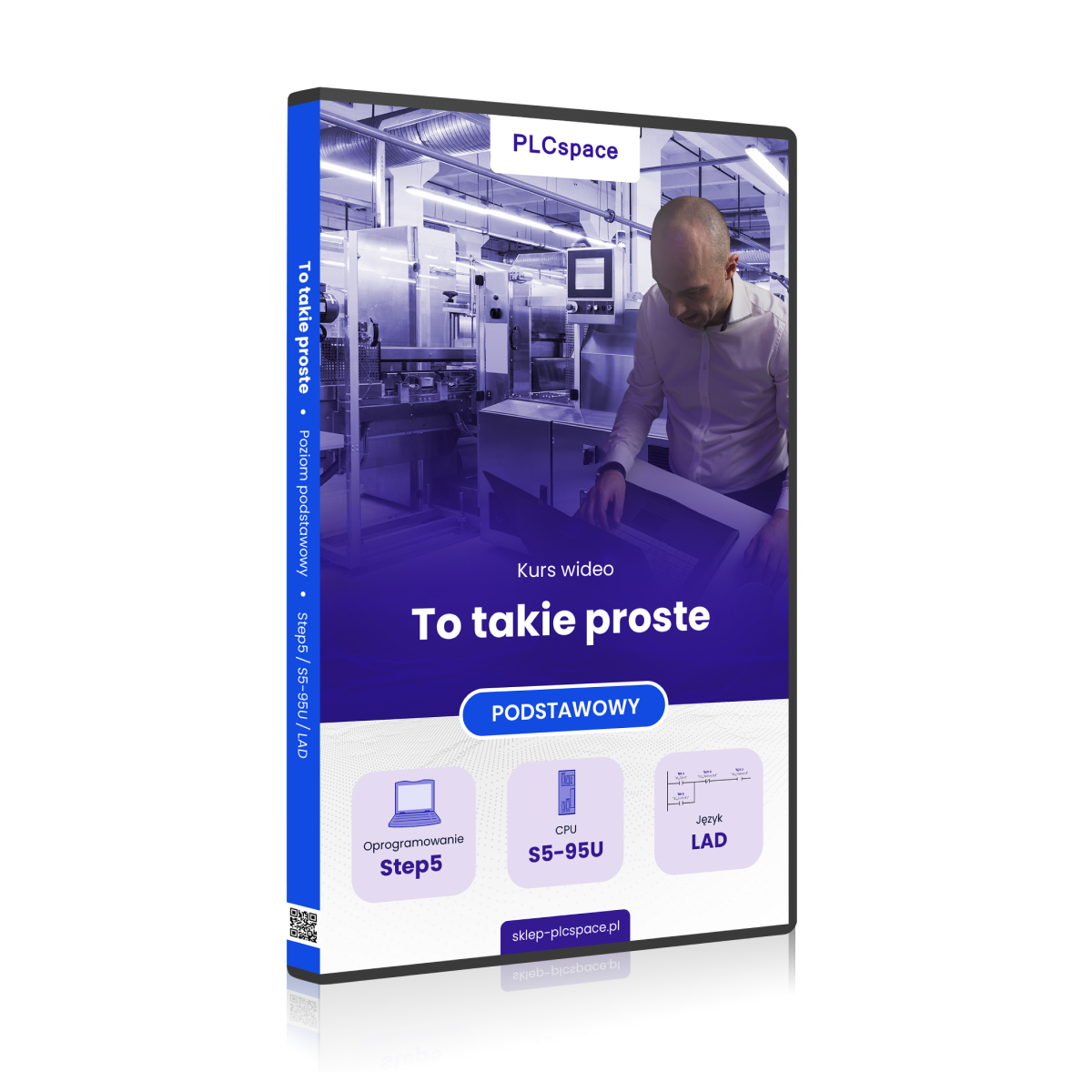

It's that simple

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

479.00 zł – 499.00 zł

What will you get from us besides gaining programming knowledge?

For people who have never had a little exposure to programming training before, the S5 course may seem complicated before starting. Nothing could be further from the truth! Our aim is to give you the basic knowledge so that you feel at ease with PLC technology. We have prepared carefully designed aids for you to help you solve many of the problems you will encounter in practice on your own. We offer you:

Simatic S5 PLC programming course - it's that easy! Basic level. Step5 software

The industrial automation course on the Simatic 5 controller is designed for anyone who has acquired a technical education and wants to start their adventure in automation, but does not know how to take the first steps in this industry. You may have a great deal of theoretical knowledge, but without experience it is difficult to get a really interesting and developmental job.

This training course is therefore designed to equip you with the practical skills to program PLCs. Once you have completed it, you will learn how they work and how to configure them, and you will learn to solve problems that occur on a daily basis in the industrial sector.

Programmable logic controllers are the backbone of many automation-based companies. They are used in logistics, manufacturing, transport and forwarding or the production of machinery and components. Siemens PLCs are used in conveyor belts, overhead cranes or packaging machines. Their use is so popular because they greatly facilitate repetitive tasks and speed up technological processes.

If you dream of working in the automation industry, want to program industrial equipment, design entire transmission lines or take care of traffic control, this course is ideal for you. It's a big dose of condensed knowledge of PLC programming basics that will make the basics of controller programming simple for you.

What is this Siemens Simatic S5 PLC programming course about?

The course is taught in such a way that complete beginners will gain the most from it. If you don't have knowledge of Siemens controller programming, here you will gain it and consolidate it. You will build your programming skills on the S5-95U Simatic S5 CPU, which appeared on the market back in the late 1970s. Although Siemens officially withdrew it from sale a few years ago, you will still encounter it in many factories.

The Simatic S5 module was available in several base variants with many different types of processor, differing in clock speed, amount of available memory and range of capabilities. Some of the Simatic S5 chips were used in the pharmaceutical industry, providing extremely high precision performance.

This basic course is designed for anyone who wants to understand how simple industrial modules work. It is also a close match to the Siemens Simatic S7-1200 controller. If you are planning to develop your passion further, this would be a great course to start with.

During the course, you will use the Step 5 V 7.23 development environment, a Siemens controller programming tool that you can download free of charge from the manufacturer's website. You can also use an older version of the Step 5 V 6.6 simulator. If you are not sure how to configure the software panel in order to start learning, don't worry. We will explain everything to you.

Programming the Simatic 5 controller is possible in several languages, but for the purposes of PLC training we will be concerned with learning the so-called LAD. This is a graphical programming language that resembles the structure of an electrical circuit with its structure. It is liked by programmers because of its easy and readable syntax and clear control.

What should a beginner PLC programmer in Simatic S5 bear in mind?

Note that the PLC course is about a fairly old module, so make sure you have the right equipment before you start your first training course. In addition to the course itself, you will need:

- programming cable (e.g. Amsamotion with authorisation number 6ES5-734-1BD20);

- a computer with built-in RS-232 and Windows XP or higher operating system;

- format the files on the partition as FAT32.

Find out that Siemens PLC programming in the LAD language doesn't have to be complicated and you can learn it without any prior practice. If you're tired of flicking through thick books filled to the brim with tables, formulae and knowledge that often can't be put into practice, that's great. Sit back and find out why you should sign up for PLCSpace training!

Knowledge test:

Is this course for you? Take this test MULTIPLE choice to check it out.

Key information about the course

We give you more than just a simple beginners' course. We will reveal to you the arcana of the work of professionals and show you issues that you have certainly not encountered at school. And all in an accessible format.

Although you may think of the PLC profession as working solo, in practice you will very often have to coordinate your projects with a whole host of specialists and managers. We will teach you this too.

Many PLC courses teach schematic actions that lead to beginners repeating the same mistakes. With us, you will learn to avoid the pitfalls and find creative solutions.

After our course, you will not be thrown in at the deep end at work. With the Factory I/O application, you will test how the various solutions present themselves and see how they translate into practice.

We have many years of PLC programming behind us and want to share our knowledge and experience with you. Learn effective programming practices and operate effectively.

Benefits of the Siemens Simatic PLC programming course

You will find plenty of tutorials on the market for people wanting to explore the basics of controller programming, but our training is a whole different level. What a really great course can look like.

Sample lesson / What you will do after the course

Find out about the PLC basics training programme

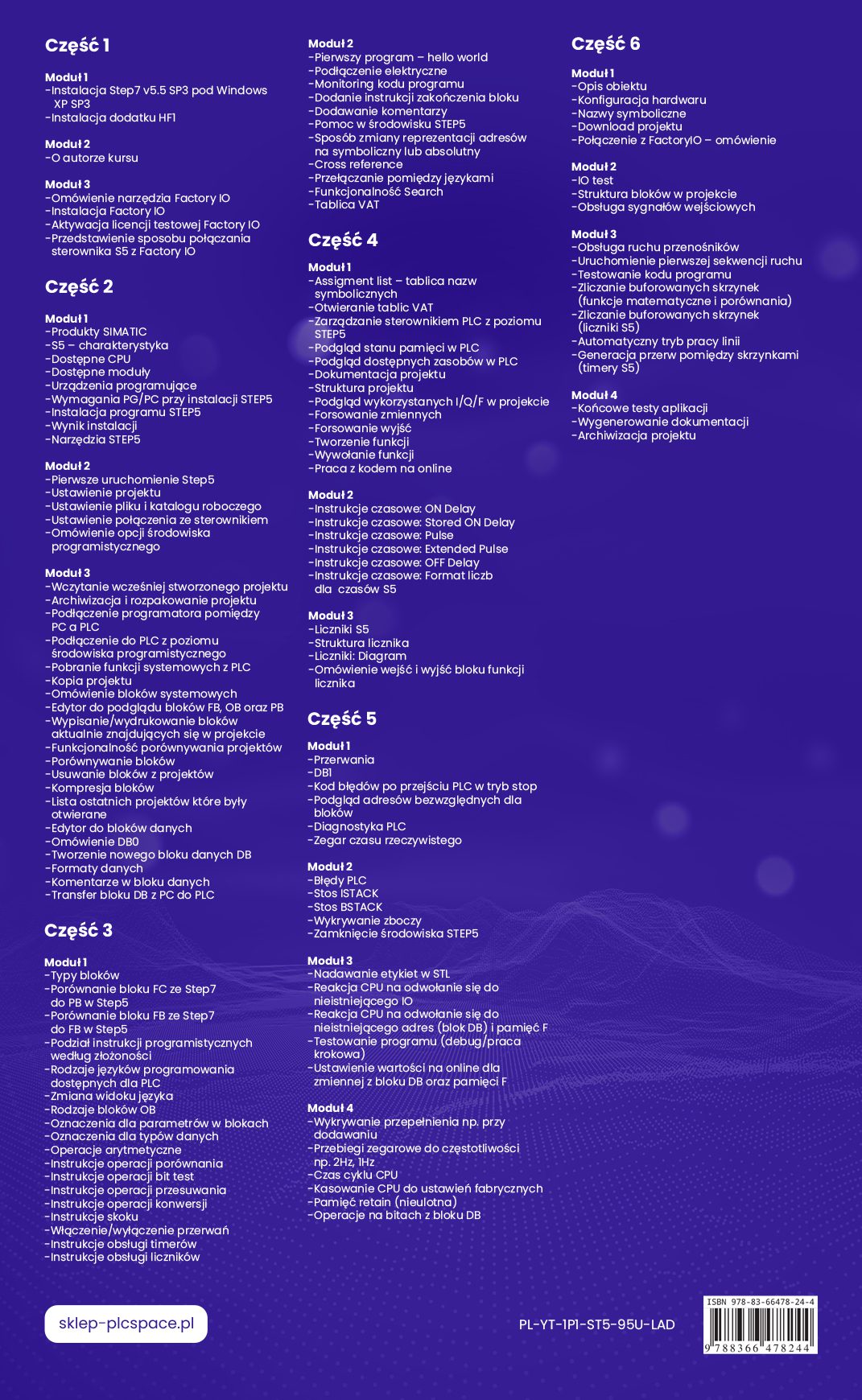

The entire training is divided into 6 parts, each of which is dedicated to different groups of issues.

After completing all modules, you will have practical knowledge of Simatic S5 controller programming that you can use in your daily activities. Rediscover the value of training and sign up for a course organised by PLC Space.

-

Module 1

- Step7 v5.5 SP3 installation under Windows

XP SP3 - Installation of additive HF1

- Step7 v5.5 SP3 installation under Windows

-

Module 2

- About the course author

-

Module 3

- Overview of the Factory IO tool

- Factory IO installation

- Activation of the Factory IO test licence

- Demonstration of how to connect

S5 controller with Factory IO

-

Module 1

- SIMATIC products

- S5 - characteristics

- Available CPU

- Available modules

- Programming equipment

- PG/PC requirements for STEP5 installation

- Installation of STEP5

- Result of installation

- STEP5 tools

-

Module 2

- Initial start-up of Step5

- Project set-up

- Setting up a file and a working directory

- Setting up the connection to the controller

- Discussion of environmental options

programming

-

Module 3

- Loading a previously created project

- Archiving and unpacking the project

- Connection of the programmer between

PC vs PLC - Connection to the PLC from the

the development environment - Downloading system functions from the PLC

- Copy of the draft

- Discussion of the system blocks

- Editor to view FB, OB and PB blocks

- Printing out/printing blocks

currently in the project - Project comparison functionality

- Comparing blocks

- Removal of blocks from projects

- Compression of blocks

- List of recent projects that were

opening - Editor for data blocks

- Overview of the DB0

- Creation of a new DB data block

- Data formats

- Comments in the data block

- DB block transfer from PC to PLC

-

Module 1

- Types of blocks

- Comparison of the FC block with Step7

to PB in Step5 - Comparison of the FB block with Step7

to FB in Step5 - Division of programming instructions

by complexity - Types of programming languages

available for PLC - Changing the language view

- Types of OB

- Designations for parameters in blocks

- Designations for data types

- Arithmetic operations

- Instructions for comparison operations

- Bit test operation instructions

- Instructions for movement operations

- Instructions for conversion operations

- Jump instructions

- Enabling/disabling interrupts

- Operating instructions for timers

- Operating instructions for meters

-

Module 2

- First programme - hello world

- Electrical connection

- Programme code monitoring

- Addition of block termination instruction

- Adding comments

- Assistance in the STEP5 environment

- How to change the representation of addresses

on a symbolic or absolute - Cross reference

- Switching between languages

- Search functionality

- VAT table

-

Module 1

- Assigment list - array of names

symbolic - Opening VAT tables

- PLC management from

STEP5 - PLC memory status overview

- Overview of available resources at the PLC

- Project documentation

- Project structure

- Preview of the I/Q/F used in the project

- Forcing variables

- Forced exits

- Creation of functions

- Function call

- Working with code online

- Assigment list - array of names

-

Module 2

- Timing instructions: ON Delay

- Timing instructions: Stored ON Delay

- Timed instructions: Pulse

- Timed instructions: Extended Pulse

- Timed instructions: OFF Delay

- Time instructions: Number format

for S5 times

-

Module 3

- S5 counters

- Counter structure

- Counters: Diagram

- Discussion of the inputs and outputs of the function block

counter

-

Module 1

- Interruptions

- DB1

- Error code when PLC enters stop mode

- Preview of absolute addresses for

blocks - PLC diagnostics

- Real-time clock

-

Module 2

- PLC errors

- ISTACK stack

- BSTACK stack

- Slope detection

- Closure of STEP5 environment

-

Module 3

- Labelling in STL

- The reaction of the CPU to the reference

of a non-existent IO - The reaction of the CPU to the reference

non-existent address (DB block) and memory F - Programme testing (debug/work

step) - Setting the value to online for

variable from the DB block and the F memory

-

Module 4

- Overfill detection, e.g. at

adding - Clock to frequency

e.g. 2Hz, 1Hz - CPU cycle time

- CPU reset to factory settings

- Retention memory (non-volatile)

- Bit operations from the DB block

- Overfill detection, e.g. at

-

Module 1

- Facility description

- Hardwire configuration

- Symbolic names

- Download project

- Connection to FactoryIO - overview

-

Module 2

- IO test

- Structure of the blocks in the project

- Handling of input signals

-

Module 3

- Handling conveyor traffic

- Start of first movement sequence

- Programme code testing

- Counting of buffered boxes

(mathematical functions and comparisons) - Counting of buffered boxes

(S5 counters) - Automatic line mode

- Generation of gaps between boxes

(S5 timers)

-

Module 4

- Final application tests

- Generation of documentation

- Project archiving

Software and hardware used

CPU S5-95u

The SIMATIC S5 system family includes programmable controllers of all performance levels, i.e. from the simplest and smallest to advanced PLCs. SIMATIC S5-95u are particularly suitable for automation tasks where the control system tasks are quite simple (high demands on response times and additional functions).

Step5 software

The Step5 programming tool is the software for the hardware of the SIMATIC S5 family. It allows you to create hardware descriptions (hardware configuration) and test program code for all S5 PLCs. In addition, documentation for the entire automation project can be prepared.

Factory IO

Typical machine scenarios can be run in Factory IO, and the virtual factory connects to the SIM PLC simulator (or the actual PLC. Programming of the controller is possible in the programming environment (depending on the PLC family), and insight into its operation is available during the online connection

What will you be able to do after completing the course?

Wondering what you'll be able to do after a PLC programming course? Check out the options available - you'll find that a solid practical knowledge will open many doors for you. What industries will you find employment in?

Forget about learning dry theory. Put it down to practice. Get yourself noticed on the job market and become a sought-after specialist. And all this without an ounce of monotonous rulebook learning, just ready-made solutions!

Guarantee

and certificate

If, after 14 days of purchase, you find that it is not for you, I will refund 100% of the course price. Upon completion of the course, you will receive a certificate in two languages - Polish and English.

Frequently asked questions

-

Will I receive a confirmation after my purchase?

Yes, you receive an email. Sometimes emails end up in SPAM or other folders. Please check your mailbox carefully.

-

Is there a difference between the media on which the course can be ordered?

No. The material is the same regardless of the type of storage medium. At the time of purchase, you decide which type of data carrier you choose, i.e. online, DVD or USB.

-

Which PLC programming language should I choose when starting out?

If you are an electrician then LAD. If there has been any exposure to text-based languages (C, C++, C#, Java, etc) then SCL. If there has been no exposure to any programming at all then the basic course is LAD and SCL (the solution to each task is shown in two languages).

-

Is this course for me if I have never used a PLC?

Yes. The basic courses are just set up so that people with no exposure to Siemens PLCs can learn such skills. The student is guided step by step (as can also be seen in the course table of contents).

-

What tools are used for consultation?

Consultations take place via Skype or TeamViever.

-

How do I make an appointment for a consultation?

Please send an email to biuro@plcspace.pl with your questions (problems) and suggestions for a convenient date for your consultation (via Skype or Teamviever).

-

How long are the consultations valid?

This is 60 calendar days from the date of purchase.

-

Can I deliver the course on different computers?

Yes. The course material (videos) can be viewed on any computer.

-

What does the online version of the course look like?

You receive the course by email, where there are private links to the videos.

-

What if a problem arises during the course?

Please email me with a description of the problem at: biuro@plcspace.pl.

-

What is the access time for the course?

No time limits for any medium (i.e. online, DVD or USB version).

-

Do I need to have any experience with programming?

No. The basic course gives step-by-step all the information needed from 'scratch'.

-

Will I need to purchase a licence for the Factory IO software?

No. There is information in the course on how to obtain licences to complete the material.

-

Will I need to purchase a licence for the PLC development environment?

No. There is information in the course on how to obtain licences to complete the material.

-

Is it possible to return the course?

Yes.

-

Will I need a PLC to deliver the course?

No. A real controller is not necessary. The course is designed in such a way that it can also be completed on a virtual controller. It all depends on what the trainee has at their disposal.

-

How do I buy a course?

Just click Add to basket and complete the form and make payment.

-

When does the course start?

-> Online version - immediately after payment

-> Physical version - when you receive the package from the carrier.

Buy as a set and save

Select at least 2 courses from the list and the first free book item (three selections in total) and an automatic discount of 25% will be calculated in your basket.

If you want to find out more about a particular course, click on its name and the page will take you to its offerings.

Companies that have benefited from our courses

Feedback from students

Stanislaw

Stanislaw

What sets this course apart is the opportunity to acquire practical, concrete knowledge. Everything is clearly explained. Definitely recommended!

Marcel

Marcel

After going through the course, I know what the components of the programming environment are and what to do step by step. Now I feel confident and know what I am doing

Leon

Leon

Course delivered in a very accessible way. Contains a lot of interesting and useful information.

Michael

Michael

I can honestly recommend the course. It is solid and factual knowledge. I will definitely be buying more.

Victor

Victor

Thanks to the course, I have decided to go further in this direction. The goal is to look for a more challenging and better job

Peter

Peter

The course prepared by Mr Tomasz is distinguished by its high level of content and meticulously prepared lessons. They are planned in a clear and sensible manner, making it easier to assimilate knowledge and return to the material if necessary. An additional advantage is the possibility of a free consultation.

Nikodem

Nikodem

Definitely recommended! The facts themselves, no unnecessary dwelling on issues.

Ignatius

Ignatius

This is my first course, certainly not my last. I am impressed with the substantive quality of the knowledge.

Tymon

Tymon

Everything clearly explained, you can really learn a lot. Lots of practical information and examples to help you remember everything. In my opinion, it is worth using this form of learning because you can learn anytime and anywhere. It is practical and convenient.

You may also be interested in:

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

0.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

99.00 zł 9.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

99.00 zł 79.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

0.00 zł