Akademia profesjonalistów PLC. Zawód przyszłości – Programista PLC.

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

272.28 € – 409.68 €

Zapis do Akademii kończy się za:

Co otrzymasz po zapisaniu się do Akademii?

Praca programisty PLC opiera się na sześciu kluczowych filarach, które są niezbędne do opanowania tej profesji. Nasza Akademia został zaprojektowany tak, abyś mógł poznawać te filary w optymalnej kolejności, zapewniając kompleksowe i skuteczne szkolenie.

- Programowanie – Naucz się podstaw i zaawansowanych technik programowania PLC, aby tworzyć efektywne i niezawodne systemy automatyki. Poznasz tajniki programowania sterowników PLC, w tym sterowników z rodziny Simatic S7. Nauczysz się programować w języku graficznym LAD oraz unikać typowych błędów początkujących. Dzięki naszym kursom będziesz pisać optymalny, przejrzysty i czysty kod.

- Wizualizacja – Poznaj narzędzia i techniki wizualizacji, które pozwolą Ci tworzyć intuicyjne interfejsy użytkownika dla systemów automatyki. Nauczysz się, jak tworzyć efektywne systemy wizualizacji procesów przemysłowych, które są intuicyjne i przyjazne dla użytkowników. Opanujesz narzędzia takie jak TIA Portal.

- Komunikacja – Zrozum różne metody komunikacji między urządzeniami PLC i innymi systemami, co jest kluczowe dla zintegrowanych rozwiązań automatyki. Poznasz najważniejsze protokoły komunikacyjne stosowane w automatyce przemysłowej, co pozwoli Ci na płynne integrowanie różnych systemów i urządzeń.

- Safety – Opanuj zasady bezpieczeństwa w systemach automatyki, aby projektować i utrzymywać bezpieczne środowiska pracy. Zdobędziesz wiedzę na temat zasad bezpieczeństwa w systemach automatyki. Nauczysz się, jak projektować i implementować systemy safety zgodne z obowiązującymi normami.

- Technika napędowa – Dowiedz się, jak kontrolować i optymalizować napędy sterujące pracą silnika w systemach automatyki, zwiększając efektywność i precyzję działania. Nauczysz się, jak optymalnie konfigurować napędy do podstawowych aplikacji spotykanych w przemyśle.

- Diagnostyka – Naucz się technik diagnostyki i rozwiązywania problemów, aby szybko i skutecznie naprawiać usterki i minimalizować przestoje.

Zapisz się do Akademii, aby uzyskać dostęp do wszystkich tych kluczowych modułów i stać się wykwalifikowanym automatykiem i programistą PLC.

Akademia dla przyszłych automatyków / programistów PLC

Jeśli jesteś początkującym w dziedzinie automatyki i programowania PLC, nasza Akademia jest dla Ciebie. Skupiamy się na osobach, które dopiero zaczynają swoją przygodę z PLC lub zrobiły już pierwszy krok, ale potrzebują solidnej podstawy i praktycznej wiedzy.

Why choose our offer?

- For beginners: Kurs jest zaprojektowany z myślą o osobach, które mają małe lub żadne doświadczenie w automatyce i programowaniu PLC.

- Kompleksowe przygotowanie: Po ukończeniu naszego szkolenia będziesz w pełni przygotowany do pracy jako automatyk i programista PLC.

- Praktyczna wiedza: Oferujemy 80% kluczowych umiejętności i wiedzy, które są najczęściej wykorzystywane w pracy. Dzięki temu unikniesz konieczności szukania informacji w internecie i metodą prób i błędów dochodzenia do rezultatów.

Dołącz do naszej Akademii i zdobądź niezbędne umiejętności, aby rozpocząć karierę w automatyce i programowaniu PLC!

Knowledge test:

Is this course for you? Take this test MULTIPLE choice to check it out.

Egzamin Summary

0 of 10 Questions completed

Questions:

Information

You have already completed the egzamin before. Hence you can not start it again.

Egzamin is loading…

You must sign in or sign up to start the egzamin.

You must first complete the following:

Results

Results

0 of 10 Questions answered correctly

Your time:

Time has elapsed

You have reached 0 of 0 point(s), (0)

Earned Point(s): 0 of 0, (0)

0 Essay(s) Pending (Possible Point(s): 0)

Categories

- Not categorized 0%

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- Current

- Review

- Answered

- Correct

- Incorrect

-

Question 1 of 10

1. Question

Can I0.0 and Q0.0 addresses be used simultaneously in the same SIMATIC S7-1500

CorrectIncorrect -

Question 2 of 10

2. Question

Is it possible to display the same variable multiple times in different numerical representations in the Watch table ?

CorrectIncorrect -

Question 3 of 10

3. Question

Can a program be uploaded to the PLC when it is in RUN mode ?

CorrectIncorrect -

Question 4 of 10

4. Question

What type of variables can be copied with the MOVE block

CorrectIncorrect -

Question 5 of 10

5. Question

What is the DEC instruction (block) used for ?

CorrectIncorrect -

Question 6 of 10

6. Question

What is the result of performing a CONV block operation on the number 2.7 if the result should be as type INT ?

CorrectIncorrect -

Question 7 of 10

7. Question

Can the CTU counter have a negative value?

CorrectIncorrect -

Question 8 of 10

8. Question

Can the FC1 function be called in the FC1 function code?

CorrectIncorrect -

Question 9 of 10

9. Question

Is it possible to stop the controller (switch to STOP mode) from the programmer (PC) ?

CorrectIncorrect -

Question 10 of 10

10. Question

What is the maximum number of time functions that can be used in a PLC?

CorrectIncorrect

Kluczowe informacje o Akademii

You will find that you are eager to reach for complementary knowledge yourself. On our course, we don't just teach the theoretical basics of programming. We show you concrete solutions, tricks and tricks that will make your work go more smoothly and faster, as well as safer for your colleagues. We teach you the analytical thinking that every PLC programmer should master.

Although the work of an automation programmer may be associated mainly with loneliness, in reality it is usually quite the opposite. PLC programmers become part of a team that works together on a single project. This means that you have to consult and discuss the results of your work with managers, logistics specialists, health and safety specialists on an ongoing basis. No worries! After our course, you will feel like a fish in water, programming PLCs for both small companies operating in a narrow specialisation and large manufacturing companies.

You will also learn how to avoid them and work on your workshop. Most PLC courses you find on the web are limited to imparting theory. However, we know that theory is far too little for beginners. We will show you how to avoid the pitfalls that lurk in your work as an industrial automation technician and explain why they can be dangerous.

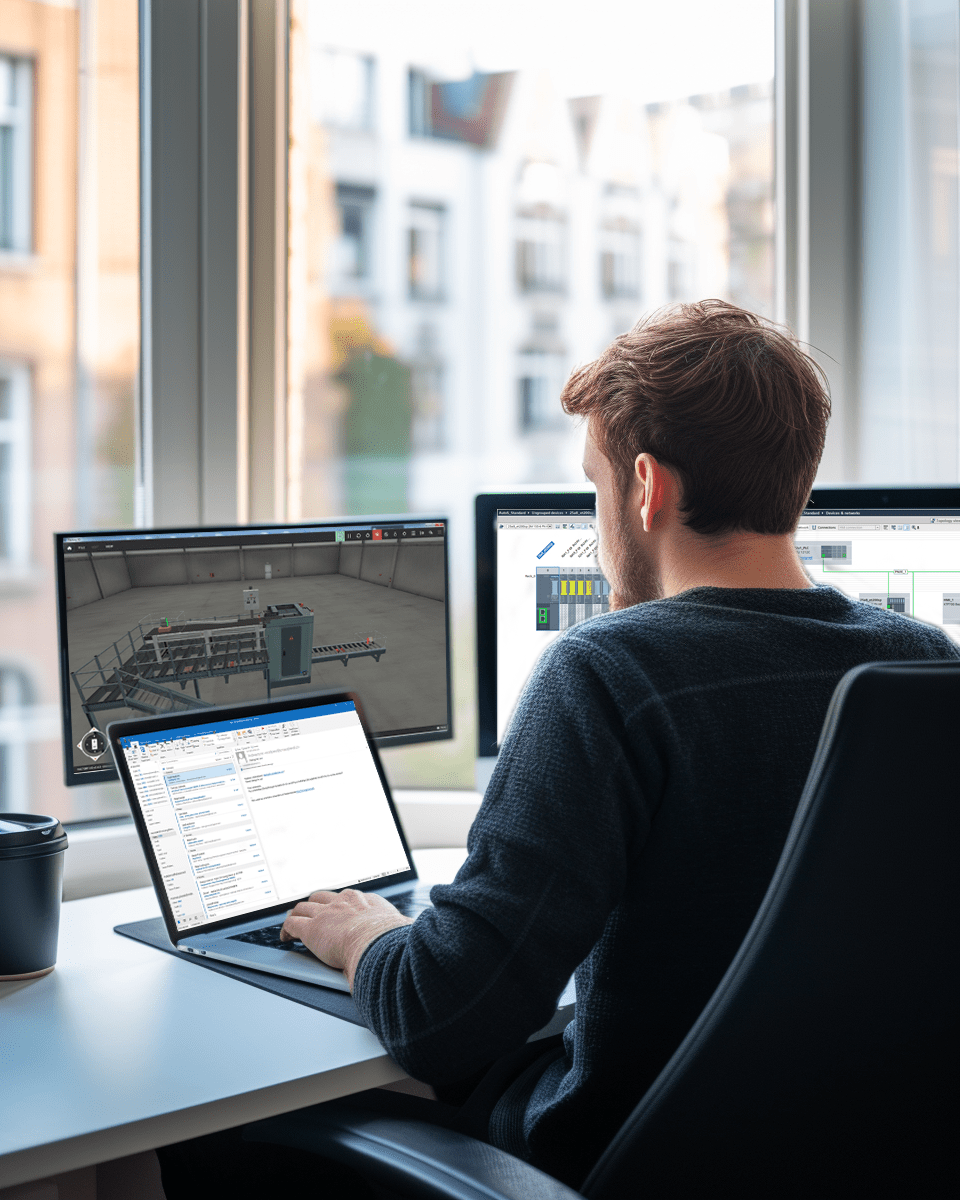

The virtual factory will show you the typical challenges faced by automation professionals working in industry, you will master the stress before the real work. With Factory I/O, you will be able to test any solution that comes to mind before you propose it in practice. With Factory I/O, you will see the results of your work right away, and you will not just look at the source code.

Software Factory IO takes you into a virtual factory where you test the operation of individual Siemens Simatic s7 PLCs in real time. Test your knowledge in practice using a secure sandbox and feel like a real automation programmer.

You learn to program the PLC in the LAD language, which allows you to write code of any level of sophistication.

Our course is delivered in a convenient online format, and you gain unlimited access to the learning materials and review them whenever you want. Forget about jotting everything down in a bulky notebook.

Uczysz się programować z wykorzystaniem sterownika PLC Siemens S7-1200 i S7-1500. To uniwersalny moduł, który sprawdzi się przy wielu prostych i złożonych projektach.

You solve the exercises on your own, without the group acting as a distraction, and you sit down to train when you have the time and inclination.

The course is conducted on a simulator that allows visualisation of the various activities.

All exercises are based on the TIA Portal platform, which you can download and use free of charge.

Z udostępnionym materiałem możesz się zapoznać niezależnie od tego, czy korzystasz z Windowsa 7, 8.1, 10 czy 11. Szkoda pieniędzy na nowy komputer, skoro Twój poprzedni doskonale poradzi sobie ze szkoleniem.

With many years of working on large projects, we pass on the best programming practices that you will use in any job. You will meet many other programmers in your career and not all of them will represent a good school of programming. We want you to join the best in your field, so we will pass on not only knowledge and practice, but also thought patterns that will help you in your future work. It's not just about you being able to design software about PLC. It's about you doing it perfectly. We can help you do that.

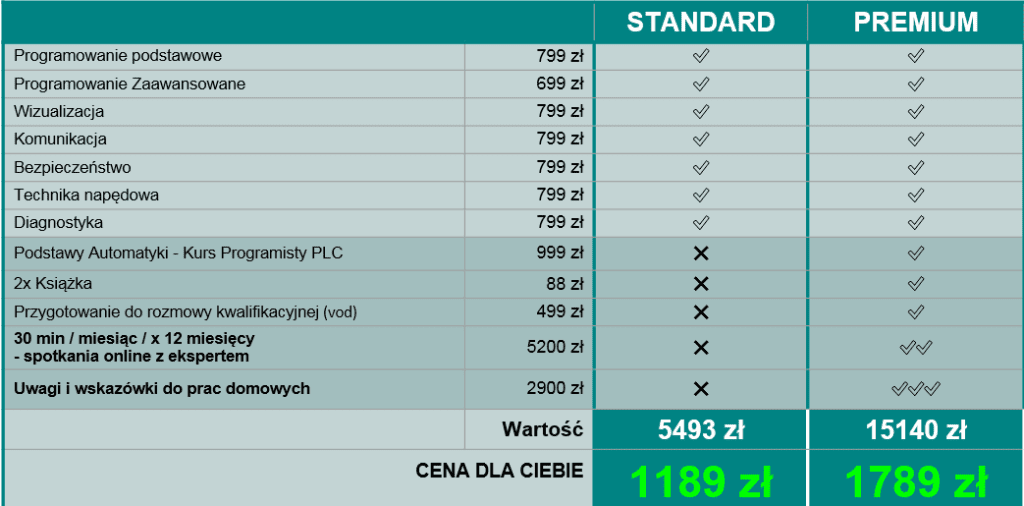

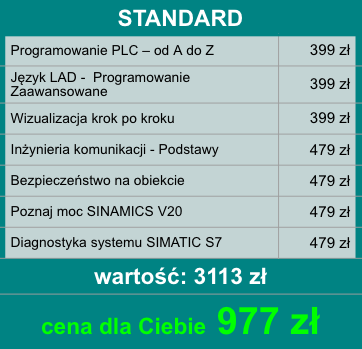

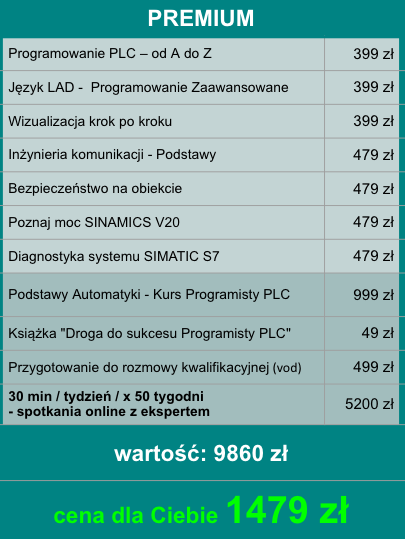

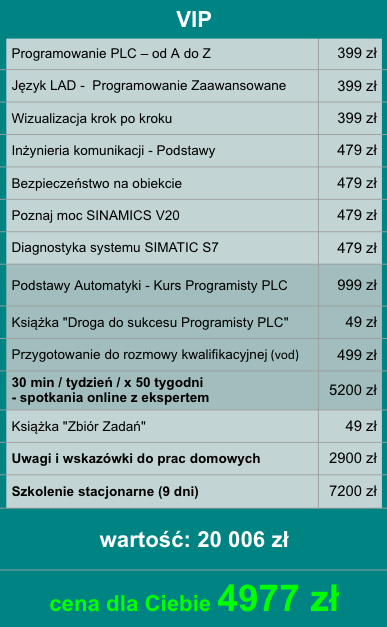

Dostępne pakiety

W ramach Akademii Profesjonalistów PLC oraz projektu „Zawód przyszłości – Programista” oferujemy kompleksowe szkolenie, które wyposaża przyszłych programistów PLC w niezbędne umiejętności do osiągnięcia sukcesu. Kluczowym aspektem tej profesji jest nie tylko umiejętność programowania samych sterowników PLC, ale także dogłębne zrozumienie urządzeń, które są do nich podłączone.

PLC programmer powinien znać i rozumieć działanie maszyn i urządzeń współpracujących ze sterownikami, aby skutecznie tworzyć programy, które zapewnią ich optymalną pracę. Wiedza ta umożliwia efektywną diagnostykę, szybkie rozwiązywanie problemów oraz wprowadzanie ulepszeń w procesach automatyzacji.

Aby osiągnąć mistrzostwo w tej dziedzinie, programista musi zmierzyć się z szeregiem typowych zadań, które pozwolą na zdobycie wprawy i doświadczenia. Nasz program szkoleniowy oferuje bogaty zestaw praktycznych ćwiczeń i rzeczywistych scenariuszy, dzięki którym uczestnicy mogą sprawdzić i doskonalić swoje umiejętności w realistycznych warunkach.

Dołącz do nas i przekonaj się, jak wiedza teoretyczna połączona z praktyką może otworzyć przed Tobą drzwi do fascynującej kariery w automatyce przemysłowej. Zyskaj pewność siebie i kompetencje, które uczynią Cię nieocenionym specjalistą na rynku pracy.

– Programowanie podstawowe(799 zł)

– Programowanie Zaawansowane (699 zł)

– Wizualizacja (799 zł)

– Komunikacja (799 zł)

– Bezpieczeństwo (799 zł)

– Technika napędowa (799 zł)

– Diagnostyka (799 zł)`

RAZEM WARTOŚĆ: 5493 PLN

Dodatkowo jako BONUS jest kurs: „Zrozumieć Automatykę – Przewodnik dla Zielonych” (499 zł)

– WSZYSTKO to, co w pakiecie STANDARD (5493 zł)

plus

– Podstawy Automatyki – Kurs Programisty PLC (999 zł)

– Książka „Droga do sukcesu Programisty PLC” (49 zł)

– Książka „SIMATIC S7-1200 w zadaniach” (39 zł)

– Przygotowanie do rozmowy kwalifikacyjnej (499 zł)

– 30 min / miesiąc / x 12 miesięcy – spotkania online z ekspertem (5200 zł)

– Uwagi i wskazówki do prac domowych przez 12 miesięcy (2400 zł)

RAZEM WARTOŚĆ: 15140 zł

Dodatkowo jako BONUS jest kurs: „Zrozumieć Automatykę – Przewodnik dla Zielonych” (499 zł)

Example lesson

Jak wygląda harmonogram Akademi Profesjonalistów PLC? (online, VOD)

- Kursant gdy dołączy do Akademii, powinien realizować zgodnie z proponowanym harmonogram.

- Udział będzie wymagał około 5 godzin pracy (średnio) w ciągu tygodnia.

- Każdy etap w ramach Akademii będzie trwał około miesiąca lub dwóch miesięcy.

- Dodatkowe dwa tygodnie będzie przeznaczone na projekty dodatkowe (stanowiące szlifowanie poznanej wiedzy i umiejętności),

- Kursant musi być gotów poświęcić odpowiednią ilość czasu na naukę i być zdeterminowany do rozwoju.

Harmonogram etapów pracy online (VOD):

(rozwiń opisy poszczególnych tygodni)

-

Tydzień 1

- [C2][M1] Pozycjonowanie modułowych sterowników S7

- [C2][M1] Pozycjonowanie S7-1500

- [C2][M1] Najważniejsze punkty systemu SIMATIC S7-1500

- [C2][M1] SIMATIC S7-1500 w TIA Portal

- [C2][M1] Przegląd dostępnych jednostek centralnych

- [C2][M1] Przegląd dostępnych modułów sygnałowych

- [C2][M1] SIMATIC S7-1500: Modularny sterownik do dużych aplikacji

- [C2][M1] SIMATIC S7-1500: Moduły

- [C2][M1] SIMATIC S7-1500: Instalacja i montaż stacji

- [C2][M1] SIMATIC S7-1500: Montaż modułu

- [C2][M1] SIMATIC S7-1500: Montaż listwy przyłączeniowej

- [C2][M1] SIMATIC S7-1500: CPU wyświetlacz → Przegląd

- [C2][M1] SIMATIC S7-1500: CPU Wyświetlacz → Menu i kolory

- [C2][M1] SIMATIC S7-1500: CPU Wyświetlacz → Operacje

- [C2][M1] SIMATIC S7-1500: Wyświetlacz CPU → Dostęp i zabezpieczenie

- [C2][M1] SIMATIC 1500: Karta pamięci → Przegląd i właściwości

- [C2][M1] SIMATIC 1500: Funkcje technologiczne

- [C2][M1] Rozproszone I/O

- [C2][M1] Pozycjonowanie rozproszonych modułów sygnałowych

- [C2][M1] Przegląd dostępnych modułów -> Rozproszone I/O

- [C2][M1] ET 200SP: Zoptymalizowany rozmiarowo system I/O

- [C2][M1] ET 200SP: Konfiguracja i maksymalna liczba modułów

- [C2][M1] ET 200MP: Modularny rozproszony system I/O

- [C2][M1] ET 200MP: Konfiguracja i maksymalna liczba modułów

- [C2][M2] TIA Portal – Kompletny system inżynierski

- [C2][M2] Przegląd oferty produktów

- [C2][M2] STEP 7 Przegląd oferty produktów

- [C2][M2] STEP 7 Licencjonowanie

-

Tydzień 2

- [C2][M2] WinCC Dostępne opcje

- [C2][M2] WinCC Licencjonowanie

- [C2][M2] Startdrive Dostępne opcje i licencjonowanie

- [C2][M2] Systemy operacyjne obsługujące oprogramowanie inżynierskie

- [C2][M2] Maszyny wirtualne (dostępne oprogramowanie)

- [C2][M2] Równoległa instalacja “Side-by-Side”

- [C2][M2] Widok portalu i projektu

- [C2][M2] Widok portalu

- [C2][M2] Widok projektu

- [C2][M2] Widok projektu

- [C2][M2] Komponenty w widoku projektu

- [C2][M2] Układ okien

- [C2][M2] Sekcje okna w obszarze roboczym

- [C2][M2] Ustawianie edytora na wierzchu w trakcie pracy

- [C2][M2] Drzewo projektu

- [C2][M2] Karty zadań

- [C2][M2] Karta zadań “Biblioteki”

- [C2][M2] Własne biblioteki użytkownika

- [C2][M2] Okno inspektora

- [C2][M2] Zapis projektu

- [C2][M2] Funkcje pomocy

- [C2][M2] Archiwizacja / Przywracanie projektów

- [C2][M2] Opcje cofania i ponawiania operacji

- [C2][M2] Skróty klawiaturowe

- [C2][M2] Język narzędzia projektowego

- [C2][M3] Narzędzia Online: Konfiguracja i parametryzacja urządzeń

- [C2][M3] Industrial Ethernet: Adres IP i maska podsieci

- [C2][M3] System operacyjny Windows

-

Tydzień 3

- [C2][M3] Dostęp Online

- [C2][M3] Dostępne urządzenia -> Widok portalu

- [C2][M3] Dostępne urządzenia -> Widok projektu i Dostęp Online do CPU

- [C2][M3] Dostęp Online do CPU: Diagnostyka, ustawienia i wybór trybu pracy

- [C2][M3] Dostęp Online do CPU: Odczyt buforu diagnostycznego

- [C2][M3] Dostęp Online do CPU: Adres IP, nazwa urządzenia, czas, FW Update, karta pamięci MMC

- [C2][M3] Kasowanie pamięci CPU za pomocą przełącznika zmiany trybu pracy

- [C2][M3] SIMATIC 1500: Koncepcja pamięci CPU – kasowanie pamięci

- [C2][M3] SIMATIC 1500: Koncepcja pamięci CPU – przywrócenie ustawień fabrycznych

- [C2][M3] Komponenty edytora “Devices & Networks“

- [C2][M3] Konfiguracja urządzeń (Hardware Configuration)

- [C2][M3] Katalog sprzętowy (Hardware Catalog)

- [C2][M3] Tworzenie konfiguracji sprzętowej stacji

- [C2][M3] Wstawianie/kasowanie modułów

- [C2][M3] Konfiguracja: Zamiana modułów

- [C2][M3] Obszar niewykorzystywanych modułów (Not Plugged In)

- [C2][M3] Kompilacja i wczytanie konfiguracja sprzętowej (Hardware Configuration)

- [C2][M3] Istotne właściwości CPU

- [C2][M3] Właściwości CPU: Adres IP (Ethernet addresses)

- [C2][M3] Właściwości CPU: Bajt systemowy i zegara (System and Clock Memory)

- [C2][M3] Status LED

- [C2][M3] S7-1500 CPU

- [C2][M3] Diody LED modułów I/O jednostki S7-1500 CPU

- [C3][M1] Nowe oznaczenia

- [C3][M1] Zmienne globalne i lokalne

- [C3][M1] Znaczenie zmiennych i typów zmiennych

- [C3][M1] Typy danych: Elementarne typy danych

- [C3][M1] Typy danych: Złożone typy danych

-

Tydzień 4

- [C3][M1] Zmienne PLC Tags i stałe (PLC tags)

- [C3][M1] Zawartość tablicy PLC Tags

- [C3][M1] Wyszukiwanie/Zastępowanie/Sortowanie zmiennych PLC Tags

- [C3][M1] Przykład błędnej deklaracji zmiennych w tablicy PLC Tag

- [C3][M1] Kopiowanie/wklejanie tablicy zmiennych PLC Tags do Excel

- [C3][M1] Wstawianie zmiennych PLC Tag w programie użytkownika

- [C3][M1] Adresowanie absolutne i symboliczne

- [C3][M1] Zmiana nazwy/adresu (Rewiring) zmiennych PLC Tags

- [C3][M1] Definicja zmiennych z poziomu programu użytkownika

- [C3][M1] Monitorowanie zmiennych w tablicy PLC Tags

- [C3][M1] Podtrzymanie pamięci zmiennych PLC Tags

- [C3][M1] Dostęp do zmiennych PLC Tags z poziomu HMI

- [C3][M2] Zestaw szkoleniowy S7-1500

- [C3][M2] Adresacja modułów I/O stacji S7-1500

- [C3][M2] Konfiguracja stacji S7-1500

- [C3][M2] Konfiguracja stacji ET200sp

- [C3][M2] Komponenty zadawania sygnałów i wyświetlania

- [C3][M2] Uruchomienie i podłączenie Paletyzatora

- [C3][M3] Binarne operacje logiczne: AND, OR

- [C3][M3] Czujniki i symbole

- [C3][M3] Pierwsze sprawdzenie, stan sygnału, wynik sprawdzenia i wynik operacji logicznej

- [C3][M3] Ćwiczenie teoretyczne: Czujniki i symbole

- [C3][M3] Operacje binarne: Exclusive

- [C3][M3] OR (XOR)

- [C3][M3] Cewka, Set, Reset, NOT

- [C3][M3] Przerzutniki

- [C3][M3] Wykrycie zbocza sygnału

- [C3][M3] Wykrycie zbocza RLO

-

Tydzień 5

- [C4][M1] Typy bloków programu (Program Blocks)

- [C4][M1] Struktura programu

- [C4][M1] Bloki programowe STEP 7

- [C4][M1] Koncepcja i opis bloków S7

- [C4][M1] Utworzenie bloku S7

- [C4][M1] Właściwości bloków: Języki programowania, stempel czasu

- [C4][M1] Właściwości bloków: Kontrola standardu IEC i konwersja typu danych

- [C4][M1] Właściwości bloków: Ochrona Know-how

- [C4][M1] Dodatkowe atrybuty bloków S7-1200/1500

- [C4][M1] Wywołanie bloków

- [C4][M1] Segmenty programu (Block Networks)

- [C4][M1] Instrukcje programowania

- [C4][M1] Wstawianie instrukcji za pomocą “Empty box”

- [C4][M1] Instrukcje wykrycia zbocza

- [C4][M1] Monit zmiany wyniku operacji logicznej RLO

- [C4][M1] Mechanizm ENO

- [C4][M1] Konwersja typów danych

- [C4][M1] Blok operacji matematycznych (CALCULATE Box)

- [C4][M1] Instrukcje matematyczne: MIN, MAX, LIMIT

- [C4][M1] Instrukcje skoków JMP_LIST i SWITCH

- [C4][M1] Skalowanie wartości analogowych oraz bezpośredni dostęp do modułów I/O za pomocą “:P”

- [C4][M1] Skalowanie instrukcjami NORM_X i SCALE_X

- [C4][M1] Określanie zakresów IN_RANGE, OUT_RANGE, OK

- [C4][M1] Profile instrukcji

- [C4][M1] Ustawienia edytora bloków

- [C4][M1] Zamykanie/Zapis bloków

- [C4][M1] Grupowanie bloków

- [C4][M1] Porównanie bloków

-

Tydzień 6

- [C4][M1] Kompilacja pojedynczych bloków

- [C4][M1] Kompilacja pojedynczych/Wszystkich zmienionych bloków

- [C4][M1] Wczytanie bloków do CPU

- [C4][M1] Monitorowanie bloków

- [C4][M1] Kasowanie bloków

- [C4][M1] Autodetekcja konfiguracji Online

- [C4][M2] Bloki danych i ich użycie

- [C4][M2] Znaczenie zmiennych i typów zmiennych

- [C4][M2] Podstawowe typy danych w STEP 7

- [C4][M2] Typy danych dla timerów, daty i czasu

- [C4][M2] Złożone typy danych

- [C4][M2] Tworzenie globalnego bloku danych: atrybuty “Only in Load Memory” / “Optimized Block Access”

- [C4][M2] Edytor bloku danych

- [C4][M2] Wartości domyślne, startowe i aktualne zmiennych DB

- [C4][M2] Wartości Snapshot, zadane i startowe

- [C4][M2] Pamięć nieulotna, wczytanie bloku DB do CPU / odczyt z CPU

- [C4][M2] Wgrywanie zmodyfikowanych bloków DB do CPU

- [C4][M2] Dostęp do zmiennych DB z poziomu panelu HMI

- [C4][M2] Kopiowanie i wklejanie z / do Microsoft Excel

- [C4][M2] Przykład zmiennej typu ARRAY

- [C4][M2] Przykład zmiennej typu STRUCTURE

- [C4][M3] Zmienne lokalne i globalne

- [C4][M3] Zarządzanie lokalny stosem

- [C4][M3] Zastosowanie zmiennych lokalnych, tymczasowych

- [C4][M3] Parametryzacja bloków: Przykład: Obsługa błędu

- [C4][M3] Sugerowane rozwiązanie z parametryzacją bloku

- [C4][M3] Deklaracja parametrów lokalnych

- [C4][M3] Zastosowanie parametrów w obrębie bloku

-

Tydzień 7

- [C4][M3] Wywołanie bloku z parametrami

- [C4][M3] Bloki Instance DB

- [C4][M3] FB – Obszar deklaracji zmiennych

- [C4][M3] Tworzenie bloku danych Instance DB

- [C5][M1] Akwizycja, przetwarzanie i generowanie danych

- [C5][M1] Opis zadania: Zliczanie transportowanych elementów

- [C5][M1] Format liczby Integer (INT, 16-Bit Integer)

- [C5][M1] Format liczby Double Integer (DINT, 32-Bit Integer)

- [C5][M1] Format liczby REAL (Floating-point Number, 32 Bit)

- [C5][M1] Typy danych i formaty wyświetlania

- [C5][M1] Liczniki: CTU, CTD, CTUD

- [C5][M1] Instancje bloków danych liczników / timerów

- [C5][M1] Funkcje licznika: Wejścia

- [C5][M1] Funkcja licznika: Wyjścia

- [C5][M1] Funkcja timera TON

- [C5][M1] Diagram impulsowy funkcji timera TON (ON Delay)

- [C5][M1] Podstawowe funkcje matematyczne

- [C5][M1] Przepisanie wartości zmiennej

- [C5][M1] Operacje logiczne na liczbach

- [C5][M1] Operacje porównania: IN_RANGE, OUT_RANGE

- [C5][M1] Operacje daty i czasu: RD_SYS_T

- [C5][M2] Typy bloków programowych

- [C5][M2] Bloki organizacyjne S7-1500

- [C5][M2] Tworzenie nowego bloku OB

- [C5][M2] Informacja startowa OB przy użyciu OB100 (przykład)

- [C5][M2] S7-1500 Startup

- [C5][M2] Przerywanie programu cyklicznego

- [C5][M2] Przerwanie Time-of-Day (OB 10)

-

Tydzień 8

- [C5][M2] Przerwanie cykliczne (OB35)

- [C5][M2] Przesunięcie fazy dla przerwań cyklicznych

- [C5][M2] Przerwanie sprzętowe (OB 40)

- [C5][M2] Obsługa błędów asynchronicznych za pomocą bloków OB

- [C5][M2] Obsługa błędów synchronicznych za pomocą bloków OB

- [C5][M3] Wstawianie i łączenie rozproszonych I/O

- [C5][M3] Konfiguracja modułów I/O

- [C5][M3] Nadanie nazwy urządzenia (Device Name)

- [C5][M3] Parametryzacja adresów I/O

- [C5][M3] Wykorzystanie sygnałów I/O w kodzie programu

- [C5][M4] Wymiana danych pomiędzy panelem dotykowym i CPU

- [C5][M4] Dostosowanie programu S7

- [C5][M4] Dodanie panelu HMI

- [C5][M4] Interfejs konfiguracji WinCC

- [C5][M4] Przyciski i pola Wejść/Wyjść

- [C5][M4] Konfiguracja adresu IP panelu HMI

- [C5][M4] Konfiguracja połączenia panelu HMI z CPU

- [C5][M4] Łączenie HMI z CPU w jedną podsieć

- [C5][M4] Konfiguracja połączenia HMI z CPU

- [C5][M4] Wykaz adresów poszczególnych urządzeń

- [C5][M4] Ustawienia umożliwiające wczytanie projektu

- [C5][M4] Przypisanie adresu IP

- [C5][M4] Wczytanie konfiguracji sprzętowej do panelu HMI

- [C5][M4] Wstępne wymagania

- [C5][M4] Wczytanie konfiguracji sprzętowej do panelu HMI

- [C5][M4] Wprowadzenie do konfiguracji

- [C5][M4] Sekcje nawigacji

- [C5][M4] Pole I/O do odczytu i wprowadzania wartości

- [C5][M4] Wywołanie funkcji za pomocą przycisku

-

Tydzień 9

- Ćwiczenia dodatkowe

-

Tydzień 10

- Ćwiczenia dodatkowe

-

Tydzień 11

- [C2-M1] Miejsca wykorzystania

- [C2-M1] Dodanie bloku DB do projektu

- [C2-M1] Tablice (1/2)

- [C2-M1] Tablice (2/2)

- [C2-M1] Wymiary tablic

- [C2-M1] Określenie zakresu przez stałe

- [C2-M1] Bez określania zakresów [tylko w sekcji interfejsu]

- [C2-M1] Granice

- [C2-M1] Odczyt wskazanego elementu tablicy (1/2)

- [C2-M1] Odczyt wskazanego elementu tablicy (2/2)

- [C2-M1] Zapis do wskazanego elementu tablicy (1/2)

- [C2-M1] Zapis do wskazanego elementu tablicy (2/2)

- [C2-M1] Przykład funkcji obsługującej tablice

- [C2-M1] Kod funkcji

- [C2-M1] Obliczenie liczby elementów w tablicy

- [C2-M1] Odczyt z tablicowego bloku danych

- [C2-M1] Zapis do tablicowego bloku danych

- [C2-M1] Odczyt bloku danych w pamięci ładowania (1/2)

- [C2-M1] Odczyt bloku danych w pamięci ładowania (2/2)

- [C2-M1] Zapis do bloku danych w pamięci ładowania (1/2)

- [C2-M1] Zapis do bloku danych w pamięci ładowania (2/2)

- [C2-M1] Zadanie 1

- [C2-M1] Zadanie 2

- [C3-M1] Funkcje Zaokragleń

- [C3-M1] Funkcje zaokrąglenia

- [C3-M1] Zaokrąglenie do najbliższej liczby

- [C3-M1] Do góry

- [C3-M1] Do dołu

- [C3-M1] Odcięcie części po przecinku

- [C3-M1] Przegląd możliwości

- [C3-M1] Trudności

- [C3-M2] Blok startup

- [C3-M2] Ob100

- [C3-M2] Resetting retentive data

- [C3-M3] Funkcje

- [C3-M3] Bloki FC

-

Tydzień 12

- [C3-M3] Program liniowy VS modularny

- [C3-M3] Dodanie funkcji FC

- [C3-M3] Właściwości FC

- [C3-M3] Właściwość FC – NIE posiada pamięci danych pomiędzy cyklami

- [C3-M3] Widok obszaru roboczego

- [C3-M3] Wywołanie funkcji (1/2)

- [C3-M3] Wywołanie funkcji (2/2)

- [C3-M3] Download (wgranie wszystkich bloków do CPU)

- [C3-M3] Przykład

- [C3-M3] Monitorowanie kodu bloków (1/2)

- [C3-M3] Monitorowanie kodu bloków (2/2)

- [C3-M4] Lista odniesień

- [C3-M4] Cross-reference – Lista odniesień (1/2)

- [C3-M4] Cross-reference – Lista odniesień (2/2)

- [C3-M4] Zmienne tymczasowe

- [C3-M4] Zmienne tymczasowe

- [C3-M4] Pamięć w CPU

- [C3-M4] Obszar zastosowania (1/3)

- [C3-M4] Obszar zastosowania (2/3)

- [C3-M4] Obszar zastosowania (3/3)

- [C3-M4] Zmienne tymczasowe (1/2)

- [C3-M4] Zmienne tymczasowe (2/2)

- [C3-M4] Funkcje FC z parametrami

- [C3-M4] Bloki FC z parametrami

- [C3-M4] Dlaczego FC z parametrami?

- [C3-M4] Sekcja interfejsu

- [C3-M4] Przykład – Pole koła (1/5)

- [C3-M4] Przykład – Pole koła (2/5)

- [C3-M4] Przykład – Pole koła (3/5)

- [C3-M4] Przykład – Pole koła (4/5)

- [C3-M4] Przykład – Pole koła (5/5)

- [C3-M4] Przykład – użycie wielokrotne

- [C3-M4] Zastosowanie parametrów w bloku

- [C3-M4] Zadanie 1

- [C3-M4] Zadanie 2

- [C3-M5] Funkcje FB

-

Tydzień 13

- [C3-M5] Bloki FB

- [C3-M5] Różnice

- [C3-M5] Właściwości FB

- [C3-M5] Dedykowany blok danych

- [C3-M5] Dodanie funkcji FB

- [C3-M5] Tworzenie instancji (1/2)

- [C3-M5] Tworzenie instancji (2/2)

- [C3-M5] Widok obszaru roboczego

- [C3-M5] Jak wygląda wywołanie ?

- [C3-M5] Program modularny (1/2)

- [C3-M5] Program modularny (2/2)

- [C3-M5] Download (wgranie wszystkich bloków do CPU)

- [C3-M5] Monitorowanie kodu bloków (1/2)

- [C3-M5] Monitorowanie kodu bloków (2/2)

- [C3-M5] Brak podglądu kodu funkcji FC, FB – przyczyny

- [C3-M5] Brak sensu pisania w FB takiego kodu

- [C3-M5] Więcej w kursach wideo

- [C3-M6] Funkcje FB z parametrami

- [C3-M6] Bloki FB z parametrami

- [C3-M6] Dlaczego FB z parametrami?

- [C3-M6] Sekcja interfejsu

- [C3-M6] Przykład – średnia (1/5)

- [C3-M6] Przykład – średnia (2/5)

- [C3-M6] Przykład – średnia (3/5)

- [C3-M6] Przykład – średnia (4/5)

- [C3-M6] Przykład – średnia (5/5)

- [C3-M6] Przykład – użycie wielokrotne

- [C3-M6] Co trafia do instancji ?

- [C3-M6] Większa liczna parametrów

- [C3-M6] Zmiany w sekcji interfejsu

- [C3-M6] Zadanie 1

- [C3-M7] Funkcje FB – Multiinstance

- [C3-M7] FB i multi-instance

- [C3-M7] Co to jest multi-instance ?

- [C3-M7] Kiedy używać multi-instance ?

- [C3-M7] Jak stworzyć multi-instance ?

-

Tydzień 14

- [C3-M7] Przykład – średnia (1/5)

- [C3-M7] Przykład – średnia (2/5)

- [C3-M7] Przykład – średnia (3/5)

- [C3-M7] Przykład – średnia (4/5)

- [C3-M7] Przykład – średnia (5/5)

- [C3-M7] Przykład – użycie wielokrotne

- [C3-M7] Co trafia do multi-instance ?

- [C3-M7] Zadanie 1

- [C3-M7] Zadanie 1

- [C4][M1] Operacje przenoszenia danych

- [C4][M1] Przeniesienia z obszaru do obszaru (1/6)

- [C4][M1] Przeniesienia z obszaru do obszaru (2/6)

- [C4][M1] Przeniesienia z obszaru do obszaru (3/6)

- [C4][M1] Przeniesienia z obszaru do obszaru (4/6)

- [C4][M1] Przeniesienia z obszaru do obszaru (5/6)

- [C4][M1] Przeniesienia z obszaru do obszaru (6/6)

- [C4][M1] Uzupełnienie bloku zadań wartością (1/3)

- [C4][M1] Uzupełnienie bloku zadań wartością (2/3)

- [C4][M1] Uzupełnienie bloku zadań wartością (3/3)

- [C4][M1] Zamiana kolejności bajtów

- [C4][M1] Zamiana na ciąg bitów (1/2)

- [C4][M1] Zamiana na ciąg bitów (2/2)

- [C4][M1] Zamiana ciągu bitów na typ BYTE, WORD, DWORD, LWORD

- [C4][M1] Zamiana ciągu bitów na typ BYTE, WORD, DWORD, LWORD znajdujących się w tablicy

- [C4][M1] Referencja

- [C4][M1] Operacje przenoszenia danych

- [C4][M1] Zamiana UDT na ciąg bajtów

- [C4][M1] Zamiana ciągu bajtów na UDT

- [C4][M1] Zadanie 1

- [C4][M1] Zadanie 2

- [C4][M1] Zadanie 3

- [C4][M2] Bloki danych i ich użycie

- [C4][M2] Znaczenie zmiennych i typów zmiennych

- [C4][M2] Podstawowe typy danych w STEP 7

- [C4][M2] Typy danych dla timerów, daty i czasu

- [C4][M2] Złożone typy danych

-

Tydzień 15

- [C4][M2] Tworzenie globalnego bloku danych: atrybuty “Only in Load Memory” / “Optimized Block Access”

- [C4][M2] Edytor bloku danych

- [C4][M2] Wartości domyślne, startowe i aktualne zmiennych DB

- [C4][M2] Wartości Snapshot, zadane i startowe

- [C4][M2] Pamięć nieulotna, wczytanie bloku DB do CPU / odczyt z CPU

- [C4][M2] Wgrywanie zmodyfikowanych bloków DB do CPU

- [C4][M2] Dostęp do zmiennych DB z poziomu panelu HMI

- [C4][M2] Kopiowanie i wklejanie z / do Microsoft Excel

- [C4][M2] Przykład zmiennej typu ARRAY

- [C4][M2] Przykład zmiennej typu STRUCTURE

- [C4][M3] Operacje logiczne na słowach

- [C4][M3] Iloczyn logiczny

- [C4][M3] Suma logiczna

- [C4][M3] Logiczna różnica symetryczna

- [C4][M3] Negacja

- [C4][M3] Slice access

- [C4][M3] Ustawienie bitu w słowie

- [C4][M3] Odczyt najmniej znaczącego bitu w słowie

- [C4][M3] Kopiowanie wybranego wejścia na wyjście

- [C4][M3] Kopiowanie jednego z wielu parametrów wejściowych na wyjście

- [C4][M3] Kopiowanie wejścia na wielu parametrów wyjściowych

- [C4][M3] Zadanie 1 (1/2)

- [C4][M3] Zadanie 1 (2/2)

- [C4][M3] Zadanie 2

- [C4][M4] Operacje przesuwania i rotacji danych

- [C4][M4] Przesunięcie w prawo (1/2)

- [C4][M4] Przesunięcie w prawo (2/2)

- [C4][M4] Przesunięcie w lewo

- [C4][M4] Obrót bitów w prawo

- [C4][M4] Obrót bitów w lewo

- [C4][M4] Zadanie 1

- [C4][M5] Obsługa daty i czasu

- [C4][M5] Komparator – czas i data

- [C4][M5] Konwersja typów

- [C4][M5] Dodawanie czasu

- [C4][M5] Odejmowanie czasu

-

Tydzień 16

- [C4][M5] Różnica czasu

- [C4][M5] Łączenie i konwersja

- [C4][M5] Ustawienie zegara w CPU

- [C4][M5] Odczyt zegara w CPU

- [C4][M5] Odczyt czasu lokalnego

- [C4][M5] Ustawienia czasu

- [C4][M5] Zapis czasu lokalnego

- [C4][M5] Odczyt czasu systemowego

- [C4][M5] Zadanie 1

- [C5][M1] Operacje na znakach i łańcuchach znaków

- [C5][M1] Kopiowanie

- [C5][M1] Porównanie

- [C5][M1] Konwersja (1/11)

- [C5][M1] Konwersja (2/11)

- [C5][M1] Konwersja (3/11)

- [C5][M1] Konwersja (4/11)

- [C5][M1] Konwersja (5/11)

- [C5][M1] Konwersja (6/11)

- [C5][M1] Konwersja (7/11)

- [C5][M1] Konwersja (8/11)

- [C5][M1] Konwersja (9/11)

- [C5][M1] Konwersja (10/11)

- [C5][M1] Konwersja (1/11)

- [C5][M1] Określenie długości łańcucha znaków

- [C5][M1] Konwersja łańcucha na wartość szesnastkową

- [C5][M1] Zamiana wartości szesnastkowej na ciąg znaków

- [C5][M1] Ilość znaków w łańcuchu

- [C5][M1] Łączenie łańcuchów

- [C5][M1] Odczyt fragmentu łańcucha od lewej strony

- [C5][M1] Odczyt fragmentu łańcucha od prawej strony

- [C5][M1] Odczyt środkowego fragmentu łańcucha

- [C5][M1] Usunięcie fragmentu łańcucha

- [C5][M1] Wstawienie łańcucha w łańcuch

- [C5][M1] Zamiana fragmentu łańcucha

- [C5][M1] Wyszukanie fragmentu łańcucha w innym łańcuchu

- [C5][M1] Zadanie 1

-

Tydzień 17

- [C5][M2] Funkcje matematyczne

- [C5][M2] Potęga

- [C5][M2] Pierwiastek

- [C5][M2] Logarytm

- [C5][M2] Eksponenta

- [C5][M2] Sinus

- [C5][M2] Cosinus

- [C5][M2] Tanges

- [C5][M2] Arcus sinus

- [C5][M2] Arcus cosinus

- [C5][M2] Arcus tanges

- [C5][M2] Oddzielenie części ułamkowej

- [C5][M2] Potęgowanie

- [C5][M2] Zadanie 1

- [C5][M2] Zadanie 1 – rozwiązanie

- [C5][M2] Zadanie 2

- [C5][M3] Przerwania

- [C5][M3] Dostępne bloki OB

- [C5][M3] Przerwania – zasada działania

- [C5][M3] Pominięcie PIQ oraz PII

- [C5][M3] Przerwanie sprzętowe

- [C5][M3] Przerwanie sprzętowe – zarządzanie

- [C5][M3] Przerwania cykliczne

- [C5][M3] Zarządzanie przerwaniami cyklicznymi(1/2)

- [C5][M3] Zarządzanie przerwaniami cyklicznymi(2/2)

- [C5][M3] Przerwania Time-of-day(1/3)

- [C5][M3] Przerwania Time-of-day(2/3)

- [C5][M3] Przerwania Time-of-day(3/3)

- [C5][M3] Przerwania Time-delay(1/2)

- [C5][M3] Przerwania Time-delay(2/2)

- [C5][M3] Zarządzanie przerwaniami(1/2)

- [C5][M3] Zarządzanie przerwaniami(2/2)

- [C5][M3] DIS_IRT

- [C5][M3] EN_IRT

- [C5][M3] DIS_AIRT

- [C5][M3] EN_AIRT

-

Tydzień 18

- [C5][M3] Zadanie 1

- [C5][M3] Zadanie 2

- [C5][M4] Instrukcje skoku

- [C5][M4] Etykieta + instrukcja

- [C5][M4] Skok jeśli RLO = 1

- [C5][M4] Skok jeśli RLO = 0

- [C5][M4] Lista skoków

- [C5][M4] SWITCH(1/2)

- [C5][M4] SWITCH(2/2)

- [C5][M4] Return(1/2)

- [C5][M4] Return(2/2)

- [C5][M4] Błąd

- [C5][M4] Dodanie instrukcji zakończenia bloku

- [C5][M4] Pętla

- [C5][M4] Zadanie 1

- [C5][M4] Zadanie 1 – rozwiązanie

- [C5][M4] Zadanie 2

- [C5][M4] Zadanie 3 – Sortowanie

- [C5][M5] SCL

- [C5][M5] Ogólny zapis

- [C5][M5] Instrukcja warunkowa

- [C5][M5] CASE(1/3)

- [C5][M5] CASE(2/3)

- [C5][M5] CASE(3/3)

- [C5][M5] Pętla FOR(1/3)

- [C5][M5] Pętla FOR(2/3)

- [C5][M5] Pętla FOR(3/3)

- [C5][M5] Pętla WHILE(1/2)

- [C5][M5] Pętla WHILE(2/2)

- [C5][M5] REPEAT(1/2)

- [C5][M5] REPEAT(2/2)

- [C5][M5] CONTINUE

- [C5][M5] EXIT

- [C5][M5] CONTINUE oraz EXIT w pętlach

- [C5][M5] GOTO

- [C5][M5] RETURN

- [C5][M5] Zadanie 1

- [C5][M5] Zadanie 1 – Wyszukanie wartości maksymalnej w tablicy

- [C5][M5] Zadanie 2 – Wyszukanie wartości maksymalnej w tablicy

- [C5][M5] Zadanie 3 – Sortowanie bąbelkowe

-

Tydzień 19

- Ćwiczenia dodatkowe

-

Tydzień 20

- Ćwiczenia dodatkowe

-

Tydzień 21

- [C2-M1] Główne komponenty systemu TIA Portal

- [C2-M1] Komponenty WinCC

- [C2-M1] Enginneering system -> edytory

- [C2-M1] Enginneering system -> opcje

- [C2-M1] Enginneering system -> wymagania sprzętowe i systemowe

- [C2-M1] Runtime -> wersje

- [C2-M1] Runtime -> opcje

- [C2-M1] Runtime -> wymagania sprzętowe i systemowe

- [C2-M1] Licencje

- [C2-M1] Urządzenia HMI

- [C2-M1] Wymagania do użycia projektów w WinCC

- [C2-M1] Wersje systemów operacyjnych (image version)

- [C2-M1] Koncepcja migracji paneli

- [C2-M2] Komponenty do konfiguracji GUI

- [C2-M2] Widoki środowiska

- [C2-M2] Drzewo projektu i karty zadań

- [C2-M2] Okno inspektora

- [C2-M2] Edytory WinCC -> Otwieranie

- [C2-M2] Edytory WinCC -> praca z edytorami

- [C2-M2] Edytory WinCC -> wyświetlanie edytorów

- [C2-M2] Edytory WinCC -> właściwości obiektów

- [C2-M2] Edytory WinCC -> multi zaznaczenie i edycja

- [C2-M2] Edytory WinCC -> Narzędzia panning

- [C2-M2] Edytory WinCC -> Karta zadań Layout

- [C2-M2] Tablica tagów HMI

- [C2-M2] Zarządzanie tablicą tagów

- [C2-M2] Indywidualny wygląd interfejsu użytkownika

- [C2-M2] Karta zadań Toolbox – podstawowe obiekty, elementy i kontrolki

- [C2-M2] Karta zadań Toolbox – sekcja graficzna

- [C2-M2] Karta zdań Library

- [C2-M2] Najważniejsze ustawienia środowiska

-

Tydzień 22

- [C2-M2] Archiwizacja projektu

- [C2-M2] Wykorzystanie funkcjonalności Reference project

- [C2-M2] Równoległa instalacja środowiska

- [C2-M2] Reset środowiska do ustawień domyślnych

- [C2-M3] Pliki stanowiące projekt – Opis struktury

- [C2-M3] Integracja urządzenia w projekcie – zalety

- [C2-M3] Tworzenie nowego projektu

- [C2-M3] Ustawienia językowe projektu

- [C2-M3] Dodanie urządzenia HMI do projektu

- [C2-M3] Wykorzystanie kreatora

- [C2-M3] Najważniejsze obiekty wymagające konfiguracji

- [C2-M3] Wyświetlanie alarmów systemowych

- [C2-M3] Zintegrowane połączenie z PLC

- [C2-M3] Główne ustawienia urządzenia HMI

- [C3-M1] Wymagania do wgrania

- [C3-M1] Niezbędne ustawienia w panelu HMI

- [C3-M1] Ustawienia czasu widoczności Start center

- [C3-M1] Tryb transferu dla urządzenia HMI

- [C3-M1] Kompilacja projektu

- [C3-M1] Wgranie projektu

- [C3-M1] Okno dialogowe Extended download – zaawansowane możliwości wgrania

- [C3-M1] Rozpoczęcie wgrania

- [C3-M1] Funkcjonalność Pack & Go

- [C3-M1] Wgranie projektu z wykorzystaniem karty pamięci SIMATIC

- [C3-M1] Kalibracja ekranu dotykowego w HMI

- [C3-M1] Update systemu operacyjnego w HMI (podniesienie wersji obrazu)

- [C3-M2] Podstawowe kroki przed rozpoczęciem konfiguracji

- [C3-M2] Screen management -> Ekran globalny

- [C3-M2] Screen management -> Szablon

- [C3-M2] Użycie szablonu ekranu

- [C3-M2] Definiowanie ekranu startowego

-

Tydzień 23

- [C3-M2] Sposoby przełączania ekranów

- [C3-M2] Kontrolka Graphic view

- [C3-M2] Dodawanie własnych grafik do projektu

- [C3-M2] Wyświetlanie daty i czasu

- [C3-M2] Kontrolka Button – właściwości

- [C3-M2] Kontrolka Text – właściwości

- [C3-M2] Kontrolka IO field – wyświetlanie wartości liczbowych i tekstowych

- [C3-M2] Połączenie kontrolek z tagami procesu

- [C3-M2] Tagi – dostęp absolutny i symboliczny

- [C3-M2] Kontrolka Switch

- [C3-M2] Listy tekstowe i graficzne

- [C3-M2] Dynamizacja obiektów i kontrolek

- [C3-M2] Konfiguracja i użycie ekranów Pop-up

- [C3-M2] Konfiguracja i użycie ekranów Slide-in screen

- [C3-M2] Konfiguracja limitów dla wprowadzanych wartości procesowych

- [C3-M2] Praca ze stylami

- [C4-M1] Synchronizacja czasu

- [C4-M1] Stacyjki (Faceplate) – Przegląd

- [C4-M1] Stacyjki (Faceplate) – tworzenie

- [C4-M1] Stacyjki (Faceplate) – właściwości

- [C4-M1] Stacyjki (Faceplate) – komponenty

- [C4-M1] Stacyjki (Faceplate) – Obszar roboczy

- [C4-M1] Stacyjki (Faceplate) – obszar konfiguracji

- [C4-M1] Stacyjki (Faceplate) – użycie na ekranach wizualizacji

- [C4-M1] Stacyjki (Faceplate) – aktualizacja

- [C4-M1] Stacyjki (Faceplate) – edycja istniejącej

- [C4-M1] Stacyjki (Faceplate) – funkcjonalności

- [C4-M2] Przegląd ogólny alarmowania o błędach w systemach SIMATIC

- [C4-M2] Komponenty i właściwości alarmów

- [C4-M2] Klasy alarmów

- [C4-M2] Zatwierdzanie pojawiających się alarmów

-

Tydzień 24

- [C4-M2] Dostępne ustawienia dla alarmów

- [C4-M2] Alarmy dyskretne i analogowe

- [C4-M2] Wyświetlanie alarmów na HMI

- [C4-M2] Kontrolki do alarmów

- [C4-M2] Oznaczenia pojawiających się alarmów – klasyfikacja

- [C4-M2] Filtrowanie pojawiających się alarmów

- [C4-M2] Logowanie alarmów – przegląd

- [C4-M2] Logowanie alarmów – konfiguracja

- [C4-M2] Logowanie alarmów – wyświetlanie

- [C4-M2] Logowanie alarmów – aktualizacja

- [C4-M3] Struktura administracji użytkownikami

- [C4-M3] Jak działa zabezpieczenie dostępu

- [C4-M3] Struktura autoryzacji

- [C4-M3] Konfiguracja autoryzacji

- [C4-M3] Powiązanie autoryzacji z obiektem

- [C4-M3] Konfiguracja grup użytkowników

- [C4-M3] Konfiguracja użytkowników

- [C4-M3] Hasła i ustawienia zabezpieczeń

- [C4-M3] Ustawienia do logowania

- [C4-M3] Hierarchia grup użytkowników

- [C4-M3] Praca z użytkownikami na panelu HMI (na runtime)

- [C4-M3] Konfiguracja okna dialogowego do logowania

- [C4-M3] Powiązanie zmiany użytkownika z dziennikiem zdarzeń

- [C4-M4] Idea logowania wartości procesowych

- [C4-M4] Dostępne sposoby zapisu danych – przegląd

- [C4-M4] Rodzaje/metody zapis danych

- [C4-M4] Procedura konfiguracja logu danych

- [C4-M4] Wyświetlanie zalogowanych danych

- [C4-M4] Trendy – powiązanie z logiem

- [C4-M4] Trendy – najważniejsze ustawienia

- [C4-M4] Trendy – formatowanie wyglądu

-

Tydzień 25

- Ćwiczenia dodatkowe

-

Tydzień 26

- Ćwiczenia dodatkowe

-

Tydzień 27

- [C3-M1] Typy urządzeń PROFINET IO

- [C3-M1] Model komunikacji PROFINET

- [C3-M1] Adresowanie urządzeń PROFINET

- [C3-M1] Organizacja użytkowników PROFIBUS

- [C3-M1] Koncepcja proxy PROFINET

- [C3-M1] Porównanie PROFINET IO i PROFIBUS DP

- [C3-M2] Edytor topologii

- [C3-M2] Topologie

- [C3-M2] Adres MAC

- [C3-M2] Ethernet przemysłowy: Adres IP i maska podsieci

- [C3-M2] Podział adresu IP

- [C4-M1] Wstawianie rozproszonych wejść/wyjść do projektu (Widok sieci)

- [C4-M1] Konfigurowanie połączenia z CPU i ustawianie parametrów adresu

- [C4-M1] Konfigurowanie rozproszonych wejść/wyjść (Widok urządzeń)

-

Tydzień 28

- [C4-M1] Zapisywanie nazwy urządzenia w urządzeniu IO (Inicjalizacja urządzenia)

- [C4-M2] Dodawanie urządzenia PROFINET IO

- [C4-M2] Przypisywanie CPU i nazw urządzeń

- [C4-M2] Przypisywanie adresów protokołu internetowego (IP)

- [C4-M2] Konfigurowanie czasu cyklu IO

- [C4-M3] Funkcjonalność urządzenia I-device

- [C4-M3] Właściwości i zalety urządzenia I-device

- [C4-M3] Charakterystyka urządzenia I-device

- [C4-M3] Wymiana danych między wyższym a niższym poziomem systemu IO

- [C4-M3] Konfigurowanie urządzenia I-device

- [C4-M4] Przydatne informacje o instrukcjach do komunikacji S7

- [C4-M4] GET: Odczyt danych z zdalnej CPU

- [C4-M4] PUT: Zapis danych do zdalnej CPU

- [C4-M5] TSEND_C: Nawiązywanie połączenia i wysyłanie danych

-

Tydzień 29

- [C4-M5] TRCV_C: Nawiązywanie połączenia i odbieranie danych

- [C4-M6] Pliki GSD dla urządzeń IO

- [C4-M6] Instalowanie pliku GSD

- [C4-M6] Usuwanie pliku GSD

- [C4-M6] Wyszukiwanie nieużywanych plików GSD

- [C4-M6] Zmiana wersji pliku GSD

- [C4-M7] Wprowadzenie

- [C4-M7] Zasada działania

- [C4-M7] Sekwencja podstawowych funkcji

- [C4-M7] Program PC “TCP File Server”

- [C4-M7] Projekt w portalu TIA

- [C4-M7] Opis interfejsu “TcpClient”

- [C4-M7] Blok danych “Parametry”

- [C4-M7] Blok danych “SendArrayData”

-

Tydzień 30

- [C4-M7] Przypisanie parametrów

- [C4-M7] Obsługa serwera plików TCP

- [C4-M7] Obsługa klienta TCP

- [C4-M7] Obsługa błędów

- [C4-M7] Funkcjonalność w CPU S7 (klient TCP)

- [C4-M7] Funkcjonalność na PC (serwer plików TCP)

- [C4-M7] Interakcja między klientem TCP a serwerem plików TCP

- [C5-M1] Wskaźniki LED stanu

- [C5-M1] Panel operatora CPU dla CPU online

- [C5-M1] Monitorowanie czasu cyklu i użycia pamięci

- [C5-M1] Wyświetlanie zdarzeń diagnostycznych w CPU

- [C5-M1] Przeprowadzanie porównania topologii online/offline

- [C5-M2] Funkcja do zapisu do bufora

- [C5-M2] Odczyt diody sygnalizacyjnej

- [C5-M2] Funkcje do sprawdzenia stanu urządzenia sieciowego

-

Tydzień 31

- Ćwiczenia dodatkowe

-

Tydzień 32

- Ćwiczenia dodatkowe

-

Tydzień 33

- [C2-M1] Koncepcja bezpieczeństwa

- [C2-M1] Dyrektywy

- [C2-M1] Dyrektywa maszynowa

- [C2-M1] Ocena ryzyka

- [C2-M1] Ocena zgodności

- [C2-M1] Projektowanie systemu bezpieczeństwa

- [C2-M1] Określenie PL – norma EN ISO 13849

- [C2-M1] Określenie SIL – norma EN 62061

- [C2-M1] Klasyczna implementacja systemu bezpieczeństwa

- [C2-M1] Zintegrowane bezpieczeństwo (Safety integrated)

- [C2-M2] Historia SIMATIC Safety

- [C2-M2] TIA Portal – Safety Basic

- [C2-M2] Zalety stosowania

- [C2-M2] CPU rodziny S7-1200F

- [C2-M2] Moduł F-DI

- [C2-M2] Moduły F-DQ

-

Tydzień 34

- [C3-M1] Technologia bezpieczeństwa

- [C3-M1] System ze zintegrowanym bezpieczeństwem

- [C3-M1] Wymagany hardware

- [C3-M1] Wymagany software

- [C3-M1] Komunikacja z wykorzystaniem PROFIsafe

- [C3-M1] Program bezpieczeństwa

- [C3-M2] Kategorie podłączeń

- [C3-M2] Klasyczne przykłady podłączeń

- [C3-M2] Podłączenie modułów do PLC

- [C3-M2] Podłączenie czujników jednokanałowo

- [C3-M2] Podłączenie czujników dwukanałowo

- [C3-M2] Szeregowe podłączenie

- [C3-M2] Podłączenie stycznika

- [C4-M1] Aktywacja Fail safe w CPU

- [C4-M1] Ustawienie czasów monitorowania przesyłu danych

- [C4-M1] Ochrona hasłem

-

Tydzień 35

- [C4-M1] Ogólne parametry F-DI

- [C4-M1] Parametryzacja kanału w module F-DI

- [C4-M1] Monitorowanie zakłóceń

- [C4-M1] Adresy F-destination

- [C4-M1] Ogólne parametry F-DO

- [C4-M1] Parametry kanału F-DO

- [C4-M1] Testy

- [C4-M2] Program użytkownika F-CPU

- [C4-M2] Bloki programu bezpieczeństwa

- [C4-M2] Struktura przetwarzania programu safety

- [C4-M2] Grupa F-runtime

- [C4-M2] Tworzenie funkcji F-FC oraz F-FB

- [C4-M2] Biblioteka certyfikowanych funkcji bezpieczeństwa

- [C4-M2] Konfigurator – safety administration

- [C4-M2] Sygnatura

- [C4-M2] Maksymalny czas cyklu

-

Tydzień 36

- [C4-M2] Typy dany danych dla części Fail safe

- [C4-M2] Ustawienia

- [C4-M2] Kompilacja programu bezpieczeństwa

- [C4-M2] Transfer programu bezpieczeństwa

- [C4-M2] Testowanie programu bezpieczeństwa

- [C4-M2] Blok danych ze statusami programu bezpieczeństwa – F-RTG1SysInfo

- [C5-M1] Testy okablowania

- [C5-M1] Pasywacja modułów

- [C5-M1] Blok danych F-I/O

- [C5-M1] Reintegracja

- [C5-M1] Wskazówki do programowania

- [C5-M1] Wymiana danych pomiędzy programem standardowym a safety

- [C5-M1] Dostęp do obrazu procesu i bloków DB

- [C5-M1] Sprawdzenie wiarygodności

- [C5-M1] Watch table dla wejść oraz wyjść safety

- [C5-M1] Wykorzystanie funkcji ESTOP1

- [C5-M1] Obsługa funkcji FDBACK

-

Tydzień 37

- Ćwiczenia dodatkowe

-

Tydzień 38

- Ćwiczenia dodatkowe

-

Tydzień 39

- [C2M1] Rodzaje przekształtników produkowanych przez firmę SIEMENS

- [C2M1] Rodzina SINAMICS V20

- [C2M1] Zestawienie możliwości

- [C2M1] Zestawienie parametrów

- [C2M1] Budowa przekształtnika SINAMICS V20

- [C2M1] Połączenie opcjonalnego filtra i dławika

- [C2M1] Schemat SINAMICS V20

- [C2M1] Prawidłowe podłączenie przekształtnika

- [C2M1] Sposoby sterowania silnikiem z przekształtnika

-

Tydzień 40

- [C2M1] Oprogramowanie narzędziowe

- [C2M2] Funkcje edycyjne klawiszy panela BOP

- [C2M2] Prezentacja parametrów na BOP w trakcie edycji

- [C2M2] Zakres wyświetlanych parametrów na panelu BOP

- [C2M2] Szybkie uruchamianie silnika

- [C2M2] Możliwe źródła wartości zadanej i sygnału sterującego

- [C2M2] Podgląd parametrów pracy przekształtnika na panelu BOP

- [C3M1] Ustawienia parametrów silnika i sposobu sterowania

- [C3M1] Jednostki mocy dla danego kraju i sposób sterowania momentem

-

Tydzień 41

- [C3M1] Określenie trybu pracy przekształtnika

- [C3M1] Zdefiniowanie sposobu sterowania przekształtnikiem

- [C3M1] Przypisanie parametrów granicznych dla silnika

- [C3M1] Przeliczenie ustawień silnika po dokonaniu konfiguracji

- [C3M1] Zapis ustawień do przekształtnika

- [C3M1] Komunikat o identyfikacji parametrów silnika

- [C3M1] Testowe uruchomienie silnika

- [C3M1] Przypisanie odpowiednich funkcji do wejść cyfrowych

- [C3M1] Modyfikacja parametrów rampy dla napędu

-

Tydzień 42

- [C3M1] Przykładowe zastosowanie wyjść cyfrowych

- [C4M1] Nawiązanie połączenia z konfigurowanym napędem

- [C4M1] Przywrócenie ustawień fabrycznych w napędzie

- [C4M1] Okno powitalne

- [C4M1] Ustawienia wstępne

- [C4M1] Definicja parametrów dla napędu

- [C4M1] Drzewo parametrów dla napędu

- [C4M1] Sprawdzenie dostępności napędu

- [C4M1] Dostęp do pełnej listy parametrów napędu

-

Tydzień 43

- Ćwiczenia dodatkowe

-

Tydzień 44

- Ćwiczenia dodatkowe

-

Tydzień 45

- [C2M1] Diody LED

- [C2M1] Web server

- [C2M1] HMI

- [C2M2] Jak się podłączyć do nieznanego CPU

- [C2M2] Bufora

- [C2M2] Widok sieci

- [C2M2] Widok Connection

- [C2M2] Monitoring kodu

-

Tydzień 46

- [C2M2] Monitorowanie struktury zagnieżdzeń

- [C2M2] Monitorowanie DB oraz instance DB

- [C2M2] Watch table

- [C2M2] Forsowanie

- [C2M2] Compare online/offline

- [C2M2] Trace

- [C2M2] Alarmy użytkownika

- [C2M2] Cross reference

-

Tydzień 47

- [C2M2] Wyświetlenie użyć zmiennej

- [C2M3] Otwarcie projektu ze starszej wersji TIA Portal

- [C2M3] Historia projektu TIA Portal

- [C2M3] Czas cyklu, zużycie pamięci, zużycie zasobów komunikacyjnych

- [C2M3] Najważniejsze opcje hardwarowe, które powodują problemy

- [C2M3] Bloki OB – reakcja na błędy

- [C2M3] Kopie zapasowe (upload all, upload software)

- [C2M3] Suma kontrolna

-

Tydzień 48

- [C2M3] Archiwizacja projektu

- [C2M3] Zabezpieczenia (PLC, projekt, blok, zapis, odczyt)

- [C2M3] Firmware update

- [C2M3] Zamiana urządzenia w projekcie (model sprzętu, wersja firmware)

- [C2M3] Reference project

- [C2M3] Wydruk projektu

- [C2M4] Generacje S7-1200 – o czym trzeba pamiętać

- [C2M4] Karta pamięci

-

Tydzień 49

- Ćwiczenia dodatkowe

-

Tydzień 50

- Ćwiczenia dodatkowe

Dodatkowe książki, kursy i szkolenia!

Wszystkie informacje przedstawione wyżej stanowią ABSOLUTNĄ PODSTAWĘ merytoryczną do opanowania i zawarte są w pakiecie STANDARD czyli teoria na VOD oraz Szkolenie stacjonarne (8 dni pracy pod okiem ekspertów).

Jeśli jednak poważnie myślisz o rozwoju swojej kariery w pakiecie PREMIUM dodaję dla Ciebie dodatkowo

- Podstawy Automatyki – Kurs Programisty PLC (999 zł)

- Dwie książki (88 zł)

- Przygotowanie do rozmowy kwalifikacyjnej – vod (499 zł)

30 min / miesiąc / x 12 miesiące – spotkania online z ekspertem (999 zł)

- Uwagi i wskazówki do prac domowych przez 12 miesięcy (999 zł)

Fundamentals of Automation - PLC Developer Course

WARTOŚĆ: 999 zł

Ten kompleksowy program jest skierowany do przyszłych i obecnych programistów PLC oraz osób chcących poszerzyć swoją wiedzę w tej dynamicznej dziedzinie.

Kurs zapewnia kluczowe umiejętności i wiedzę na temat urządzeń stosowanych w szafach sterowniczych, co pozwoli Ci imponować swoimi kompetencjami w pracy. Nauczysz się skutecznie dobierać i eksploatować te urządzenia, zdobywając uznanie przełożonych, współpracowników i klientów.

Kurs umożliwia naukę bez wyjazdów na szkolenia, oszczędzając czas i pieniądze. Twoje umiejętności sprzedaży i zarządzania technicznymi pracownikami się poprawią, co przełoży się na lepsze wyniki i wyższe zarobki. Zdobędziesz pewność siebie i solidne podstawy teoretyczne, ułatwiając rozmowy kwalifikacyjne i otwierając drzwi do awansu zawodowego.

Dołącz do nas, aby zdobyć wiedzę, umiejętności i pewność siebie potrzebne do pracy jako programista PLC oraz do wdrażania nowoczesnych rozwiązań automatyki. Twoje życie zawodowe i osobiste zyska nowy wymiar dzięki zdobytej wiedzy i umiejętnościom.

- Zrozumiesz technologie i koncepcje z dziedziny automatyki przemysłowej, co otworzy przed Tobą świat nowoczesnych rozwiązań w przemyśle.

- Nauczysz się obsługi różnorodnych urządzeń i systemów, zdobywając praktyczne umiejętności do efektywnej pracy w środowisku przemysłowym.

- Poznasz kluczowe zagadnienia związane z zarządzaniem procesami przemysłowymi, co umożliwi Ci skuteczne projektowanie, instalację i utrzymanie systemów automatyzacji.

- Dzięki zdobytym umiejętnościom zwiększysz wydajność i efektywność pracy, co znacząco poprawi Twoje możliwości rozwoju kariery w automatyce przemysłowej.

- Efektywniej zarządzasz procesami produkcyjnymi i przemysłowymi, lepiej osiągając cele biznesowe oraz optymalizując działania w zakresie zarządzania projektami.

Książka „Droga do sukcesu Programisty PLC”

WARTOŚĆ: 49 zł

Wyobraź sobie przyszłość jako lider w programowaniu PLC! „Droga do sukcesu Programisty PLC” to klucz do Twojego rozwoju zawodowego. Tomasz Gilewski dzieli się wiedzą i doświadczeniem na 319 stronach pełnych praktycznych wskazówek i realnych przykładów. To przewodnik, który wprowadzi Cię w świat nowoczesnej automatyzacji przemysłowej, pomoże zdobyć cenione umiejętności i zainspiruje do osiągania wyższych celów.

- Zgłębisz wprowadzenie do pracy ze sterownikami PLC, co stanowi solidny fundament w automatyce przemysłowej.

- Poznając tematykę związaną z dziedziną automatyki znacząco wpłyniesz na rozwój swojej kariery, by szybciej osiągać cele zawodowe jako Programista PLC.

Simatic S7-1200 w Zadaniach. Język LAD. Poziom Podstawowy

WARTOŚĆ: 39 zł

To praktyczny przewodnik dla osób, które chcą opanować programowanie sterowników PLC w języku LAD. Zawiera zestaw ćwiczeń, które krok po kroku pomagają zdobyć niezbędne umiejętności. Dzięki tej książce nauczysz się tworzyć projekty w różnych branżach przemysłu, takich jak automatyka czy energetyka. Praktyczne przykłady i omówienia rozwiązań wspierają rozwój kreatywności i samodzielności, jednocześnie umożliwiając zrozumienie teorii poprzez praktyczne działania w programowaniu.

To jeszcze nie koniec! Czas na pracę z ekspertami.

W ramach pakiety PREMIUM oferujemy kompleksowe wsparcie, które pomoże Ci w nauce i rozwoju zawodowym.

Otrzymujesz regularne spotkania online z ekspertami, którzy służą radą i dzielą się wiedzą, a także dostarczają cenne wskazówki do zadań domowych, pomagając Ci w doskonaleniu umiejętności.

Dodatkowo, oferujemy przygotowanie do rozmowy kwalifikacyjnej w formie lekcji wideo, abyś mógł pewnie zaprezentować swoje kompetencje i doświadczenie. Dzięki temu wszechstronnemu podejściu, zyskasz solidne podstawy i pewność siebie, niezbędne do pracy jako programista PLC.

Przygotowanie do rozmowy kwalifikacyjnej (video)

WARTOŚĆ: 999 PLN

Przygotowanie do rozmowy kwalifikacyjnej to kluczowy element drogi do sukcesu w karierze programisty PLC. Aby pomóc Ci przejść ten proces z pewnością siebie i profesjonalizmem, stworzyliśmy dedykowane lekcje wideo, które kompleksowo przygotują Cię do tego ważnego etapu.

W naszych lekcjach wideo opowiadamy szczegółowo o wszystkich aspektach, które mogą pojawić się podczas rozmowy kwalifikacyjnej. Obejmuje to:

- Sekcja A: W tej części lekcji, omawiamy kluczowe zagadnienia techniczne, które mogą być poruszane przez rekrutera. Dowiesz się, jakie pytania dotyczące programowania PLC mogą zostać zadane i jak na nie odpowiedzieć, aby zaprezentować swoją wiedzę i umiejętności w jak najlepszym świetle. Podzielimy się również przykładami pytań i odpowiedzi, które pomogą Ci przygotować się na każdą ewentualność.

- Sekcja B: W tej części skupiamy się na umiejętnościach miękkich i etykiecie rozmowy kwalifikacyjnej. Poruszamy takie tematy jak prezentowanie swojego doświadczenia, umiejętności komunikacyjne, oraz jak skutecznie budować relację z rekruterem. Nauczysz się, jak opowiadać o swoich projektach w sposób angażujący i profesjonalny, oraz jak radzić sobie z trudnymi pytaniami i sytuacjami stresującymi.

Po przejściu naszych lekcji wideo, będziesz dokładnie wiedział, jak się zachować na rozmowie kwalifikacyjnej. Otrzymasz nie tylko teoretyczną wiedzę, ale również praktyczne wskazówki i techniki, które pozwolą Ci wyróżnić się na tle innych kandydatów. Naszym celem jest, abyś czuł się pewnie i przygotowany na każdą rozmowę, niezależnie od tego, jakie pytania zostaną Ci zadane.

30 min / miesiąc / x 12 miesięcy – spotkania online z ekspertem

WARTOŚĆ: 999 zł

Nasz bootcamp stawia na bezpośredni kontakt i wsparcie uczestników też po kursie stacjonarnym, dlatego raz w miesiącu oferujemy wyjątkową okazję do spotkań online z naszymi ekspertami. Co miesiąc, przez 30 minut (lub więcej jeżeli będzie taka potrzeba), możecie uczestniczyć w sesji Q&A, gdzie jeden z naszych specjalistów jest dostępny, aby odpowiedzieć na Wasze pytania i rozwiać wszelkie wątpliwości dotyczące kursów.

How does it work?

- Terminy spotkań: Spotkania odbywają się regularnie co miesiąc. O terminach kursanci są informowani na bieżąco.

- Dostępność ekspertów: Każde spotkanie prowadzone jest przez jednego z naszych doświadczonych ekspertów, którzy specjalizują się w różnych dziedzinach, takich jak programowanie, wizualizacja, komunikacja, bezpieczeństwo, technika napędowa i diagnostyka.

- Interaktywność: Uczestnicy mają możliwość zadawania pytań na żywo poprzez czat lub mikrofon. Nasz ekspert będzie na bieżąco odpowiadał, dzieląc się swoją wiedzą i doświadczeniem.

- Link do spotkania: Każde spotkanie odbywa się za pomocą łatwo dostępnego linku, który otrzymacie w mailu. Nie wymagamy instalowania dodatkowego oprogramowania – wystarczy przeglądarka internetowa.

Co zyskujecie dzięki spotkaniom online?

- Bezpośredni kontakt z ekspertami: To unikalna okazja, aby uzyskać odpowiedzi na konkretne pytania bezpośrednio od specjalistów w danej dziedzinie.

- Rozwianie wątpliwości: Możecie na bieżąco wyjaśniać wszystkie niejasności i wątpliwości, które pojawiają się podczas realizacji kursów.

- Dodatkowe wskazówki i porady: Eksperci chętnie dzielą się praktycznymi poradami i dodatkowymi wskazówkami, które mogą pomóc w lepszym zrozumieniu materiału.

Networking: To również świetna okazja do nawiązania kontaktów z innymi uczestnikami kursu, wymiany doświadczeń i wspólnego rozwiązywania problemów.

Uwagi i wskazówki do prac domowych (maile, komentarze)

WARTOŚĆ: 999 zł

Nasza Akademia zawiera zadania do samodzielnego wykonania. Te zadania mają na celu utrwalenie wiedzy zdobytej podczas przerobionych wcześniej lekcji oraz rozwijanie praktycznych umiejętności. Poniżej znajdziecie szczegółowe informacje na temat prac domowych oraz wsparcia, jakie oferujemy.

Struktura zadań domowych

- Additional tasks: Przewidzieliśmy 12 miesięcy na realizację dodatkowych zadań. Te zadania mają na celu pogłębienie zdobytej wiedzy oraz sprawdzenie umiejętności w bardziej zaawansowanych kontekstach.

Realizacja zadań

- Samodzielność: Wszystkie zadania domowe wykonujesz samodzielnie, korzystając ze swojego komputera. Zachęcamy do samodzielnego rozwiązywania problemów i poszukiwania odpowiedzi, co jest kluczowe dla rozwoju umiejętności analitycznych.

- Wykorzystanie narzędzi i zasobów: Do realizacji zadań wykorzystujesz narzędzia i zasoby, które udostępniamy w ramach bootcampu.

Wsparcie i konsultacje

- Bezpośredni kontakt z ekspertami: Jeśli podczas wykonywania zadań napotkasz trudności lub nie będziesz pewny, czy rozwiązanie jest poprawne, zawsze możesz napisać bezpośrednio do naszego eksperta. Nasz zespół jest gotowy, aby sprawdzić Twoje zadanie i udzielić konstruktywnego feedbacku.

- Konsultacje online: Poza regularnymi konsultacjami online, oferujemy dodatkową pomoc poprzez indywidualne konsultacje. W każdej chwili możesz skontaktować się z naszym ekspertem i uzyskać wsparcie w realizacji zadań domowych.

- Feedback i poprawki: Nasi eksperci nie tylko sprawdzą Twoje zadania, ale także dostarczą szczegółowe uwagi i wskazówki, które pomogą Ci zrozumieć błędy i poprawić swoje umiejętności.

Korzyści z realizacji prac domowych

- Utrwalenie wiedzy: Regularne wykonywanie zadań domowych pozwala na lepsze przyswojenie materiału i utrwalenie zdobytej wiedzy.

- Rozwój praktycznych umiejętności: Praca nad zadaniami praktycznymi rozwija umiejętności analityczne i techniczne, które są niezbędne w pracy zawodowej.

Samodzielność i odpowiedzialność: Samodzielne wykonywanie zadań uczy odpowiedzialności i samodyscypliny, co jest kluczowe dla osiągnięcia sukcesu w nauce i pracy.

Jak wygląda BONUS ?

Kurs „Zrozumieć automatykę – Przewodnik dla zielonych” został stworzony z myślą o osobach, które dopiero zaczynają swoją przygodę z automatyką. Przedstawia on elementarne i fundamentalne zagadnienia w najprostszy i najbardziej przystępny sposób, bez skomplikowanej terminologii i zaawansowanych koncepcji. To idealne wprowadzenie dla tych, którzy chcą zrozumieć podstawy działania systemów automatyki i programowalnych sterowników logicznych (PLC), zanim przejdą do bardziej zaawansowanych tematów.

Ogólne informacje:

Kurs „Zrozumieć automatykę – Przewodnik dla zielonych” to kompleksowy przewodnik po automatyce, skierowany do osób, które dopiero rozpoczynają swoją przygodę z tym obszarem. Kurs składa się z lekcji opartych na realnych scenariuszach, które pomagają zrozumieć, jak automatyzacja wpływa na codzienną pracę w różnych branżach, w tym w piekarstwie. Uczestnicy nauczą się nie tylko podstawowych komponentów i technologii, ale także zdobędą wiedzę na temat programowania sterowników i łączenia elementów systemów automatyki.

Korzyści:

- Zrozumienie podstaw automatyki – Kurs wprowadza uczestników w kluczowe zagadnienia dotyczące automatyzacji procesów, które są niezbędne w nowoczesnym przemyśle.

- Praktyczne umiejętności – Dzięki realistycznym przykładom, takim jak automatyzacja piekarni, uczestnicy zobaczą, jak teoria przekłada się na rzeczywiste rozwiązania.

- Znajomość nowoczesnych technologii – Kurs przedstawia aktualne rozwiązania w automatyce, takie jak PLC (Programowalne Sterowniki Logiczne) i systemy automatyki oparte na modulach wejścia/wyjścia.

- Przygotowanie do pracy z systemami PLC – Uczestnicy zdobędą umiejętności programowania i konfiguracji systemów PLC oraz rozwiązywania problemów związanych z automatyzacją.

Po ukończeniu kursu uczestnicy będą potrafili:

- Zrozumieć podstawy automatyzacji – Poznają, jak maszyny mogą przejąć zadania od ludzi w różnych branżach, na przykład w piekarstwie.

- Zidentyfikować i zrozumieć elementy systemu automatyki – Nauczą się o komponentach systemu PLC, w tym o sprzęcie (hardware) oraz oprogramowaniu (software).

- Programować podstawowe operacje w PLC – Uczestnicy będą w stanie zaprogramować sterowniki PLC do podstawowych zadań sterowania maszynami.

- Zrozumieć rolę programowalnych kontrolerów logicznych (PLC) – Nauczą się, jak PLC współpracuje z innymi urządzeniami w procesie automatyzacji.

- Zarządzać pamięcią w systemach PLC – Uczestnicy zdobędą wiedzę o strukturze pamięci w PLC i jak przechowywać dane z czujników i aktuatorów.

- Adresować sygnały wejściowe i wyjściowe w PLC – Będą w stanie przypisać odpowiednie adresy do modułów wejścia/wyjścia, co pozwala na prawidłowe przetwarzanie sygnałów.

- Wykorzystać operacje logiczne w programowaniu PLC – Poznają podstawowe operacje logiczne, takie jak AND i OR, które są stosowane w programowaniu sterowników.

- Bezpiecznie łączyć moduły IO w systemach automatyki – Nauczą się, jak podłączyć i skonfigurować rozproszone oraz centralne moduły wejścia/wyjścia w systemach automatyki.

- Dbać o bezpieczeństwo w procesie produkcji – Uczestnicy będą świadomi zagrożeń związanych z pracą maszyn i będą umieli zastosować zasady BHP w automatyzacji.

Table of contents:

-

Sytuacja początkowa i rozwiązanie (1/5)

W lekcji przedstawiono problem właściciela piekarni, który zmaga się z niedoborem czasu na produkcję wypieków. Właściciel rozważa wprowadzenie automatyzacji, aby zwiększyć wydajność produkcji. Uczy się, że automatyzacja polega na tym, że maszyny wykonują zadania, które wcześniej były realizowane przez ludzi, a ich działanie jest kontrolowane przez sterownik.

-

Sytuacja początkowa i rozwiązanie (2/5)

W lekcji przedstawiono zmagania osoby zajmującej się pieczeniem chleba. Osoba ta zmaga się z ciężkimi torbami, zastanawiając się, czy nie zapomniała o czymś ważnym.

-

Sytuacja początkowa i rozwiązanie (3/5)

Lekcja dotyczy procesu produkcji pieczywa, który prowadzi właściciel piekarni. Został on podzielony na 25 różnych aktywności

-

Sytuacja początkowa i rozwiązanie (4/5)

W lekcji omówiono, jak automatyzacja wpływa na pracę piekarni. Cały proces produkcji pieczywa jest zautomatyzowany dzięki systemowi

-

Sytuacja początkowa i rozwiązanie (5/5)

W lekcji omówiono nowoczesne technologie w piekarstwie, które znacznie ułatwiają proces produkcji chleba.

-

PLC w systemie automatyki (1/3)

W lekcji omówiono rolę programowalnego kontrolera logicznego (PLC) w systemach automatyzacji, porównując go do pracy rzemieślnika

-

PLC w systemie automatyki (2/3)

Lekcja dotyczy ogólnych komponentów systemu automatyki przemysłowej, PLC (Programowalne Sterowniki Logiczne). Zostały one podzielone na dwie główne kategorie: sprzęt (hardware) i oprogramowanie (software).

-

PLC w systemie automatyki (3/3)

Lekcja dotyczy podstawowych operacji w PLC

-

Dodatkowe komponenty w systemie automatyki

Na lekcji omówiono koncepcję nowej linii produkcyjnej do pieczenia

-

Struktura i komponenty PLC

W lekcji omówiono modułową konstrukcję systemu PLC, która umożliwia dostosowanie poszczególnych elementów do specyficznych wymagań systemu automatyzacji.

-

Typy sygnałów w procesie

W lekcji omówiono proces przetwarzania sygnałów w kontekście pracy maszyn w piekarni

-

Podłączanie czujników i aktuatorów

W lekcji omówiono, jak procesor (CPU) przetwarza sygnały elektryczne z czujników i aktuatorów za pomocą modułów wejściowych i wyjściowych.

-

Typy danych w CPU (1/2)

Lekcja dotyczy zarządzania pamięcią w procesorze, w kontekście przechowywania danych z czujników i aktuatorów. W procesorze każda informacja jest przypisywana do konkretnego miejsca w pamięci, co pozwala na jej łatwe zidentyfikowanie i wykorzystanie. Każdy element danych ma przypisany typ, który określa, ile miejsca zajmuje w pamięci. Przykładem może być bit, najmniejsza jednostka pamięci, która przechowuje informacje binarne, takie jak „tak” lub „nie”. Większe jednostki, takie jak bajt (8 bitów) czy słowo (16 bitów), umożliwiają przechowywanie większych ilości danych. Lekcja ilustruje te koncepcje analogią do zarządzania nieruchomościami, gdzie każdy element ma swoje miejsce, rozmiar i właściciela, co ułatwia organizację i dostęp do informacji.

-

Typy danych w CPU (2/2)

W lekcji omówiono różne typy danych numerycznych, które są używane do przechowywania wyników obliczeń oraz wartości sygnałów analogowych. Zostały przedstawione charakterystyki tych typów, takie jak zakres wartości, obecność miejsc dziesiętnych oraz znak liczby.

-

Adresy typów danych w pamięci CPU (1/2)

W lekcji omówiono sposób adresowania pamięci w procesorach komputerowych. Zaczęto od wyjaśnienia, że pamięć jest zorganizowana w jednostki zwane bajtami, które są numerowane od zera.

-

Adresy typów danych w pamięci CPU (2/2)

W lekcji omówiono sposób, w jaki procesor (CPU) identyfikuje sygnały wejściowe i wyjściowe w pamięci. Zostało wyjaśnione, że w CPU istnieje kilka obszarów pamięci, które są oznaczone literami, co pozwala na unikalne adresowanie.

-

Adresy sygnałów wejściowych i wyjściowych (1/4)

W lekcji omówiono, jak program sterujący identyfikuje odpowiednie sygnały wejściowe i wyjściowe. Programista przypisuje zakres adresów w pamięci CPU dla każdego modułu wejściowego i wyjściowego, co umożliwia ich indywidualny dostęp.

-

Adresy sygnałów wejściowych i wyjściowych (2/4)

W lekcji omówiono sposób adresowania czujników binarnych, takich jak przyciski i przełączniki, które są klasyfikowane jako cyfrowe wejścia (DI – digital input).

-

Adresy sygnałów wejściowych i wyjściowych (3/4)

W lekcji omówiono sposób adresowania cyfrowych aktuatorów, takich jak lampy, za pomocą modułów wyjściowych. Zostało wyjaśnione, że cyfrowe wyjścia oznaczane są skrótem DQ (digital output), a ich kanały są adresowane podobnie jak kanały wejściowe.

-

Adresy sygnałów wejściowych i wyjściowych (4/4)

W lekcji omówiono adresowanie analogowych czujników i aktuatorów w systemach automatyki. Zdefiniowano skróty dla wejść analogowych (AI) oraz wyjść analogowych (AQ). Przykład modułu wejściowego z dwoma kanałami pokazuje, że zajmuje on 4 bajty pamięci CPU

-

Typy czujników - styki NO i NC

W lekcji omówiono, w jaki sposób program sterujący wykrywa aktywację przełączników i przycisków za pomocą czujników binarnych. Wyróżniono dwa typy czujników: normalnie otwarte (NO) i normalnie zamknięte (NC)

-

Binarne zapytania sygnałów w programie sterującym (1/2)

W lekcji omówiono różnice w sposobie, w jaki program sterujący odczytuje dwa typy czujników binarnych: NO (normalnie otwarty) i NC (normalnie zamknięty).

-

Binarne zapytania sygnałów w programie sterującym (2/2)

W lekcji omówiono proces przetwarzania sygnałów z czujników w programie sterującym. Sygnały te są przetwarzane w formie binarnej, co pozwala na generowanie wyników operacji logicznych.

-

Proste operacje logiczne (1/3)

W lekcji omówiono podstawowe operacje logiczne stosowane w programach sterujących, koncentrując się na operacji AND.

-

Proste operacje logiczne (2/3)

W lekcji omówiono operację logiczną OR, która jest powszechnie stosowana w programowaniu. Zostało wyjaśnione jak działa ta operacja.

-

Proste operacje logiczne (3/3)

W lekcji omówiono operacje logiczne na sygnałach binarnych oraz sposób sterowania aktuatorami binarnymi. Przykład ilustruje, jak przypisać wynik operacji logicznej do aktuatora o adresie Q 4.5.

-

Monitorowanie przepływu sygnałów

W lekcji omówiono sposoby monitorowania aktualnych sygnałów i wyników operacji logicznych w systemach inżynieryjnych.

-

Dane w CPU - systemy liczbowe (1/2)

W lekcji omówiono różne systemy liczbowe, koncentrując się na systemie dziesiętnym, binarnym i szesnastkowym.

-

Dane w CPU - systemy liczbowe (2/2)

W lekcji zwrócono uwagę, że sekwencje cyfr mogą nie wskazywać jednoznacznie na używany system liczbowy, dlatego ważne jest stosowanie identyfikatorów.

-

Czy znasz już wszystkie podstawy ?

W lekcji omówiono podstawowe pojęcia i komponenty systemów automatyzacji, w tym sposób łączenia czujników i aktuatorów oraz przetwarzania ich sygnałów.

-

Zatrzymanie instalacji w przypadku zagrożenia

W lekcji omówiono kluczowe aspekty bezpieczeństwa w procesie produkcji pieczywa, koncentrując się na zapobieganiu obrażeniom osobistym oraz uszkodzeniom mienia.

-

Połączenia IO (1/4)

W lekcji omówiono kluczowe aspekty łączenia modułów IO w rozwiązaniach automatyzacyjnych, zwracając szczególną uwagę na znaczenie przestrzennego rozmieszczenia maszyn.

-

Połączenia IO (2/4)

W lekcji omówiono dwa główne sposoby łączenia modułów wejścia/wyjścia (IO) z jednostką centralną (CPU) w systemach automatyki.

-

Połączenia IO (3/4)

W lekcji omówiono sposób podłączania rozproszonych modułów wejścia/wyjścia (IO) do centralnej jednostki CPU w systemach automatyki.

-

Połączenia IO (4/4)

W lekcji omówiono różnice między centralnymi a rozproszonymi modułami wejścia/wyjścia (IO) w kontekście programowania sterowników.

Który Pakiet będzie dla Ciebie najlepszy?

Summary

Software and hardware used

CPU S7-1200

The new controller, which has been developed as a successor to the S7-200, is characterised by slightly weaker parameters than the S7-300 family. Several CPU versions present in the family allow selection according to project requirements.

CPU S7-1500

They are available in the classic and et200sp housing. The SIMATIC S7-1500 is a modular automation system with medium and higher performance. Different controller versions allow you to match the corresponding application. Depending on requirements, the programmable controller can be expanded with input/output modules for digital and analogue signals, as well as technology and communication modules.

TIA Portal software

Totally integrated automation is a development environment that combines PLC (programming), HMI(visualisation) and startdrive(drive technology).

Factory IO

Typical machine scenarios can be run in Factory IO, and the virtual factory connects to the SIM PLC simulator (or the actual PLC. Programming of the controller is possible in the programming environment (depending on the PLC family), and insight into its operation is available during the online connection

Dla kogo jest udział w AKADEMII ?

Nasz kurs programowania PLC i automatyki został stworzony z myślą o różnych grupach zawodowych i edukacyjnych. Jest on idealnym wyborem dla osób, które chcą zdobyć nowe umiejętności i zwiększyć swoją wartość na rynku pracy. Oferujemy kompleksowe szkolenie, które dostosowane jest do potrzeb zarówno początkujących, jak i tych, którzy chcą poszerzyć swoją wiedzę.

Niezależnie od tego, czy jesteś uczniem lub studentem, elektrykiem, specjalistą ds. utrzymania ruchu, czy inżynierem rozruchu/projektu, nasz kurs dostarczy Ci niezbędnych umiejętności i wiedzy, aby sprostać wyzwaniom w dziedzinie automatyki i programowania PLC. Dołącz do nas i rozwijaj swoją karierę dzięki praktycznym i zaawansowanym szkoleniom dostosowanym do Twoich potrzeb zawodowych.

Guarantee

and certificate

If, after 14 days of purchase, you find that it is not for you, I will refund 100% of the course price. Upon completion of the course, you will receive a certificate in two languages - Polish and English.

Najczęściej zadawane pytania:

-

Will I receive a confirmation after my purchase?

Yes, you receive an email. Sometimes emails end up in SPAM or other folders. Please check your mailbox carefully.

-

Is this course for me if I have never used a PLC?

Yes. The basic courses are just set up so that people with no exposure to Siemens PLCs can learn such skills. The student is guided step by step (as can also be seen in the course table of contents).

-

What tools are used for consultation?

Konsultacje odbywają się przez Google Meet. W niektórych sytuacjach jest wykorzystywany Skype, TeamViever.

-

How do I make an appointment for a consultation?

Please send an email to biuro@plcspace.pl with your questions (problems) and suggestions for a convenient date for your consultation (via Skype or Teamviever).

-

How long are the consultations valid?

Przez cały czas trwania Akademii.

-

Can I deliver the course on different computers?

Yes. The course material (videos) can be viewed on any computer.

-

What does the online version of the course look like?

Kurs otrzymują Państwo dostęp do platformy e-larningowej, gdzie znajdują się poszczególne lekcje.

-

What if a problem arises during the course?

Please email me with a description of the problem at: biuro@plcspace.pl.

-

What is the access time for the course?

Bez ograniczeń czasowych.

-

Do I need to have any experience with programming?

No. The basic course gives step-by-step all the information needed from 'scratch'.

-

Will I need to purchase a licence for the Factory IO software?

No. There is information in the course on how to obtain licences to complete the material.

-

Will I need to purchase a licence for the PLC development environment?

No. There is information in the course on how to obtain licences to complete the material.

-

Is it possible to return the course?

Yes.

-

Will I need a PLC to deliver the course?