The secrets of PLC programming

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

91.37 € – 114.27 €

What do you get when you enrol on a PLC programming course?

When you decide to attend your first PLC training course, you may be worried that you will be saddled with complicated knowledge, and in addition given in an indigestible way. Nothing could be further from the truth! Our training is designed to familiarise you with the basics of PLC. This is why you will receive carefully selected teaching aids:

The secrets of PLC programming. Siemens PLC programming course. Basic level LAD language

You've certainly heard about PLC programming for Siemens S7-400 Simatic controllers before. They are regarded as one of the most effective central units in process automation, which is based on a PLC. This Siemens controller is designed to manage process and machine processes in virtually all industries. Our PLC programming course is designed to help you gain practical knowledge that you will use in your work. We start our PLC training from a complete beginner's level, so it doesn't matter if you have dealt with Siemens Simatic S7 controllers before.

If you dream of working as an industrial machine automation technician but want to stop acquiring theoretical programming knowledge from boring books, you've come to the perfect place! Check out our PLC programming course and start working on your career!

What is the Siemens PLC programming course about?

The PLC programming basics course has been designed to explain everything to you from the very beginning to the intermediate level. The topics we cover during the course will be useful to you in any profession where you come into contact with industrial programming. If you want to supervise equipment such as conveyor belts or entrance gates, you have come to the right place. Knowing how to program Siemens Simatic PLCs will help you to better understand the relationships that exist between components.

Currently, the programming of Siemens Simatic S7-400 controllers is primarily done in the versatile LAD language (the so-called ladder language) and it is to this language that the programme of this training course is dedicated. PLC course topics will be discussed based on the Step7 V 5.5 environment and programming work on the Sorting Station application.

Siemens Simatic programming is convenient because it does not require you to purchase any additional software. After installing Step7, you have access to a demo version of the software, which retains full functionality for 21 days. If you are already using a previous version of Step7, you can extend it for a further 21 days. The course is video-based, so you'll be through the entire hardware setup in no time.

Do you want to find out that PLC programming training does not have to be boring at all? Tired of acquiring controller programming knowledge from thick and incomprehensible books? Our course will give you a completely different experience. Let's get started!

Knowledge test:

Is this course for you? Take this test MULTIPLE choice to check it out.

Key information about the course

You will find that you are eager to reach for complementary knowledge yourself. On our course, we don't just teach the theoretical basics of programming. We show you concrete solutions, tricks and tricks that will allow you to achieve the planned result faster, with less effort and, most importantly, in complete safety. You will learn to think and analyse problems like a real PLC programmer.

Although the work of an automation programmer may be mainly associated with solitude, in reality it is usually quite the opposite. When programming PLCs, you become part of a team and must consult and discuss the results of your work with managers, health and safety professionals and even rank-and-file employees. That's why, after our course, you will learn to create both small projects for niche industries and the extensive PLC programmes that corporations using only one type of equipment need.

You will also learn how to avoid them and work on your craft. Most PLC courses you find online are limited to imparting theory. We work differently. We show concrete situations, example mistakes and their consequences, so that you have a good understanding of why accuracy matters in the work of an automation technician.

The virtual factory will show you the typical challenges faced by automation professionals working in industry, thus mastering the stress before the real job. With Factory I/O, you will be able to test any solution that comes your way before implementing it on the real job. Test and experiment during the course, so that you act quickly, efficiently and responsibly on the job.

With many years of working on large projects, we pass on the best programming practices that you will use in any job. You will meet many other programmers in your career. Some work efficiently and according to good software development principles, others look for shortcuts. We will teach you how to become part of the former group. Master PLC programming from the inside out and surprise your employer with the efficiency of your operations.

Why choose this industrial automation course in particular?

You will find more than one Simatic PLC tutorial on the market. What makes our training stand out?

Sample lesson / What you will do after the course

What is the training in programming Simatic controllers in the LAD language?

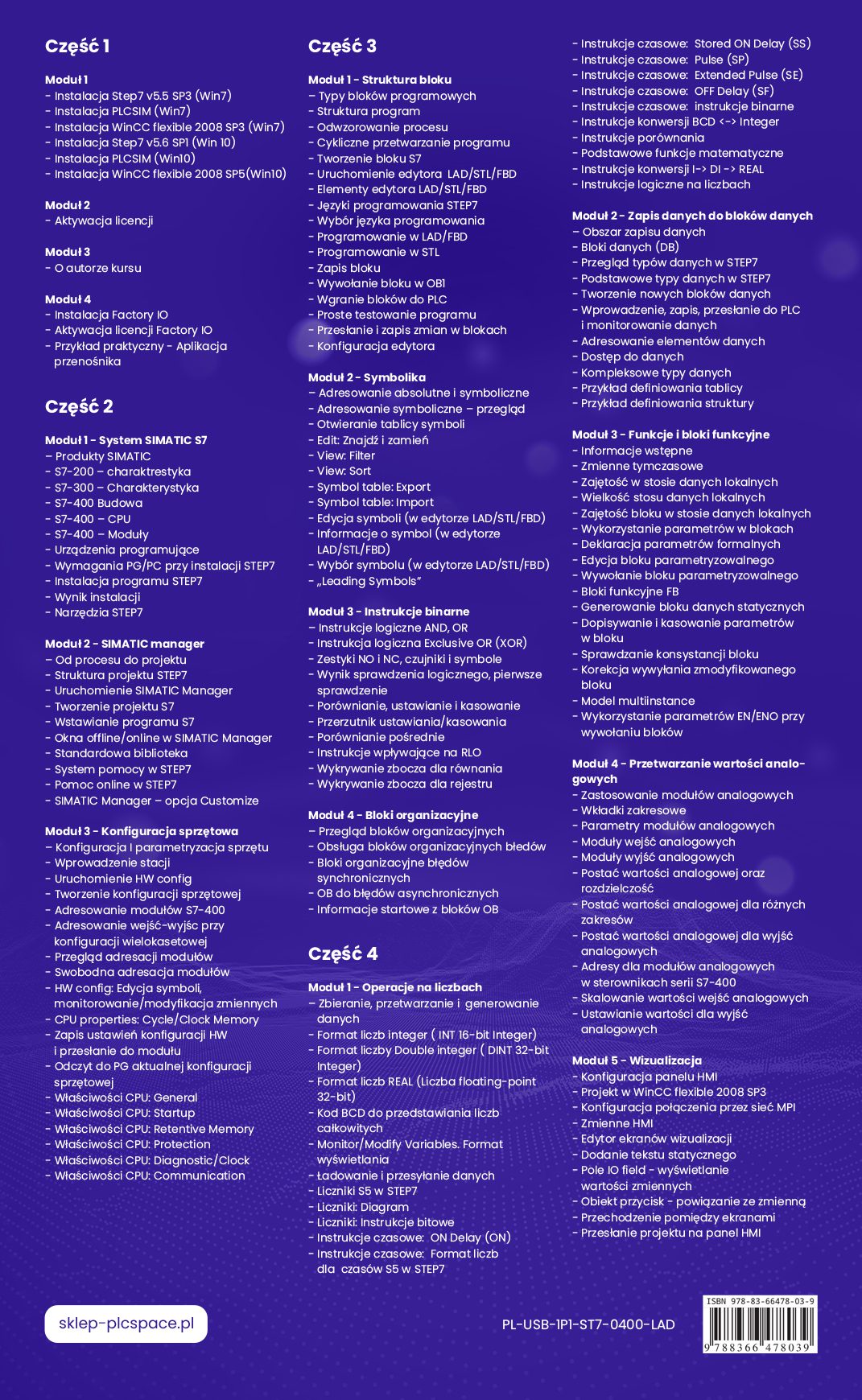

The training consists of 4 parts, divided into individual modules on specific groups of issues. In the course of them, you will learn how to control PLC modules and use them in your daily work to improve the functioning of your project. What information will you find in each part?

Once you have completed all modules, you will have a working knowledge of machine controller programming that you can use in your everyday duties. Surprise your colleagues and see for yourself that PLCs can be easy to use. Take advantage of our PLC programming course today!

-

Module 1

- Installation of Step7 v5.5 SP3 (Win7)

- PLCSIM installation (Win7)

- Installation of WinCC flexible 2008 SP3 (Win7)

- Installation of Step7 v5.6 SP1 (Win 10)

- PLCSIM installation (Win10)

- Installation of WinCC flexible 2008 SP5(Win10)

-

Module 2

- Licence activation

-

Module 3

- About the course author

-

Module 4

- Factory IO installation

- Factory IO licence activation

- Practical example - Application

conveyor

-

Module 1 - SIMATIC S7 system

- SIMATIC products

- S7-200 - charaktistics

- S7-300 - Characteristics

- S7-400 Construction

- S7-400 - CPU

- S7-400 - Modules

- Programming equipment

- PG/PC requirements for STEP7 installation

- Installation of STEP7

- Result of installation

- STEP7 tools

-

Module 2 - SIMATIC manager

- From process to design

- Structure of the STEP7 project

- Commissioning SIMATIC Manager

- Creation of the S7 project

- S7 programme insertion

- Offline/online windows in SIMATIC Manager

- Standard library

- Help system in STEP7

- Online help in STEP7

- SIMATIC Manager - Customize option

-

Module 3 - Hardware configuration

- Configuration and parameterisation of equipment

- Introduction of stations

- Running HW config

- Creation of a hardware configuration

- Addressing of S7-400 modules

- Addressing input-outputs at

multi-cassette configuration - Overview of module addressing

- Free addressing of modules

- HW config: Edit symbols,

monitoring/modification of variables - CPU properties: Cycle/Clock Memory

- Saving the HW configuration settings

and sending to the module - Reading to PG of current configuration

hardware - CPU properties: General

- CPU properties: Startup

- CPU properties: Retentive Memory

- CPU properties: Protection

- CPU features: Diagnostic/Clock

- CPU properties: Communication

-

Module 1 - Block structure

- Types of programme blocks

- Programme structure

- Process mapping

- Cyclic programme processing

- Creation of block S7

- Launching the LAD/STL/FBD editor

- Elements of the LAD/STL/FBD editor

- STEP7 programming languages

- Choice of programming language

- Programming in LAD/FBD

- Programming in STL

- Block record

- Block call in OB1

- Uploading blocks to the PLC

- Simple programme testing

- Transmission and recording of block changes

- Editor configuration

-

Module 2 - Symbolism

- Absolute and symbolic addressing

- Symbolic addressing - overview

- Opening the symbol board

- Edit: Find and replace

- View: Filter

- View: Sort

- Table symbol: Export

- Table symbol: Import

- Edit symbols (in the LAD/STL/FBD editor)

- Symbol information (in the editor

LAD/STL/FBD) - Symbol selection (in LAD/STL/FBD editor)

- "Leading Symbols"

-

Module 3 - Binary instructions

- Logical instructions AND, OR

- Exclusive OR (XOR) logic instruction

- NO and NC contacts, sensors and symbols

- The result of the logic check, the first

check - Comparison, adjustment and deletion

- Set/cancel switch

- Indirect comparison

- Instructions affecting the RLO

- Detecting the slope for the equation

- Edge detection for the register

-

Module 4 - Organisational blocks

- Overview of the organisational blocks

- Handling of organisational error blocks

- Error organisation blocks

synchronous - OB for asynchronous errors

- Starting information from OB blocks

-

Module 1 - Operations with figures

- Collection, processing and generation of

data - Integer number format ( INT 16-bit Integer)

- Double integer number format ( DINT 32-bit

Integer) - REAL number format

32-bit) - BCD code for the representation of numbers

total - Monitor/Modify Variables. Format

displays - Charging and transferring data

- S5 counters in STEP7

- Counters: Diagram

- Counters: Bit instructions

- Timed instructions: ON Delay

- Time instructions: Number format

for S5 times in STEP7 - Timing instructions: Stored ON Delay (SS)

- Timed instructions: Pulse (SP)

- Timing instructions: Extended Pulse (SE)

- Timing instructions: OFF Delay (SF)

- Time instructions: binary instructions

- BCD Integer conversion instructions

- Instructions for comparison

- Basic mathematical functions

- Conversion instructions I-> DI -> REAL

- Logical instructions on numbers

- Collection, processing and generation of

-

Module 2 - Writing data into data blocks

- Storage area

- Data Blocks (DB)

- Overview of data types in STEP7

- Basic data types in STEP7

- Creation of new data blocks

- Entry, recording, transmission to PLC

and data monitoring - Addressing of data elements

- Access to data

- Complex data types

- Example of defining an array

- Example of structure definition

-

Module 3 - Functions and Function Blocks

- Introductory information

- Temporary variables

- Occupancy in the local data stack

- Local data stack size

- Block occupancy in the local data stack

- Use of parameters in blocks

- Declaration of formal parameters

- Edit parameter block

- Calling the parameter block

- Function blocks FB

- Generation of a static data block

- Adding and deleting parameters

in the block - Checking the consistency of the block

- Modified discharge correction

block - Multi-instance model

- Use of EN/ENO parameters in

calling blocks

-

Module 4 - Analogue value processing

- Application of analogue modules

- Range inserts

- Parameters of analogue modules

- Analogue input modules

- Analogue output modules

- The form of the analogue value and

resolution - Form of analogue value for different

ranges - Analogue value form for the outputs

analogue - Addresses for analogue modules

in the S7-400 controllers - Scaling of analogue input values

- Setting values for the outputs

analogue

-

Module 5 - Visualisation

- HMI configuration

- Project in WinCC flexible 2008 SP3

- Connection configuration via MPI network

- HMI variables

- Visualisation screen editor

- Addition of static text

- IO field - display

values of the variables - Button object - link to variable

- Switching between screens

- Uploading the project to the HMI

Software and hardware used

Step7 Software

The most popular version of the classic development environment called Step7 v5.5 with Service pack 3 (can be downloaded free of charge from the Siemens website)

CPU S7-400

Factory IO

Typical machine scenarios can be run in Factory IO, and the virtual factory connects to the SIM PLC simulator (or the actual PLC. Programming of the controller is possible in the programming environment (depending on the PLC family), and insight into its operation is available during the online connection

What will you be able to do after completing the course?

Siemens PLC programming is a useful skill that is applicable to many different positions. Demand is so high that you will have the opportunity to decide for yourself which specialisation suits you best.

Say no to dry theory without being reflected in practical skills. With our solution-oriented training, you will excel in the job market - even if your programming adventure is just beginning.

Guarantee

and certificate

If, after 14 days of purchase, you find that it is not for you, I will refund 100% of the course price. Upon completion of the course, you will receive a certificate in two languages - Polish and English.

Frequently asked questions

-

Will I receive a confirmation after my purchase?

Yes, you receive an email. Sometimes emails end up in SPAM or other folders. Please check your mailbox carefully.

-

Is there a difference between the media on which the course can be ordered?

No. The material is the same regardless of the type of storage medium. At the time of purchase, you decide which type of data carrier you choose, i.e. online, DVD or USB.

-

Which PLC programming language should I choose when starting out?

If you are an electrician then LAD. If there has been any exposure to text-based languages (C, C++, C#, Java, etc) then SCL. If there has been no exposure to any programming at all then the basic course is LAD and SCL (the solution to each task is shown in two languages).

-

Is this course for me if I have never used a PLC?

Yes. The basic courses are just set up so that people with no exposure to Siemens PLCs can learn such skills. The student is guided step by step (as can also be seen in the course table of contents).

-

What tools are used for consultation?

Consultations take place via Skype or TeamViever.

-

How do I make an appointment for a consultation?

Please send an email to biuro@plcspace.pl with your questions (problems) and suggestions for a convenient date for your consultation (via Skype or Teamviever).

-

How long are the consultations valid?

This is 60 calendar days from the date of purchase.

-

Can I deliver the course on different computers?

Yes. The course material (videos) can be viewed on any computer.

-

What does the online version of the course look like?

You receive the course by email, where there are private links to the videos.

-

What if a problem arises during the course?

Please email me with a description of the problem at: biuro@plcspace.pl.

-

What is the access time for the course?

No time limits for any medium (i.e. online, DVD or USB version).

-

Do I need to have any experience with programming?

No. The basic course gives step-by-step all the information needed from 'scratch'.

-

Will I need to purchase a licence for the Factory IO software?

No. There is information in the course on how to obtain licences to complete the material.

-

Will I need to purchase a licence for the PLC development environment?

No. There is information in the course on how to obtain licences to complete the material.

-

Is it possible to return the course?

Yes.

-

Will I need a PLC to deliver the course?

No. A real controller is not necessary. The course is designed in such a way that it can also be completed on a virtual controller. It all depends on what the trainee has at their disposal.

-

How do I buy a course?

Just click Add to basket and complete the form and make payment.

-

When does the course start?

-> Online version - immediately after payment

-> Physical version - when you receive the package from the carrier.

Buy as a set and save

Select at least 2 courses from the list and the first free book item (three selections in total) and an automatic discount of 25% will be calculated in your basket.

If you want to find out more about a particular course, click on its name and the page will take you to its offerings.

Companies that have benefited from our courses

Feedback from students

Stanislaw

Stanislaw

What sets this course apart is the opportunity to acquire practical, concrete knowledge. Everything is clearly explained. Definitely recommended!

Marcel

Marcel

After going through the course, I know what the components of the programming environment are and what to do step by step. Now I feel confident and know what I am doing

Leon

Leon

Course delivered in a very accessible way. Contains a lot of interesting and useful information.

Michael

Michael

I can honestly recommend the course. It is solid and factual knowledge. I will definitely be buying more.

Victor

Victor

Thanks to the course, I have decided to go further in this direction. The goal is to look for a more challenging and better job

Peter

Peter

The course prepared by Mr Tomasz is distinguished by its high level of content and meticulously prepared lessons. They are planned in a clear and sensible manner, making it easier to assimilate knowledge and return to the material if necessary. An additional advantage is the possibility of a free consultation.

Nikodem

Nikodem

Definitely recommended! The facts themselves, no unnecessary dwelling on issues.

Ignatius

Ignatius

This is my first course, certainly not my last. I am impressed with the substantive quality of the knowledge.

Tymon

Tymon

Everything clearly explained, you can really learn a lot. Lots of practical information and examples to help you remember everything. In my opinion, it is worth using this form of learning because you can learn anytime and anywhere. It is practical and convenient.

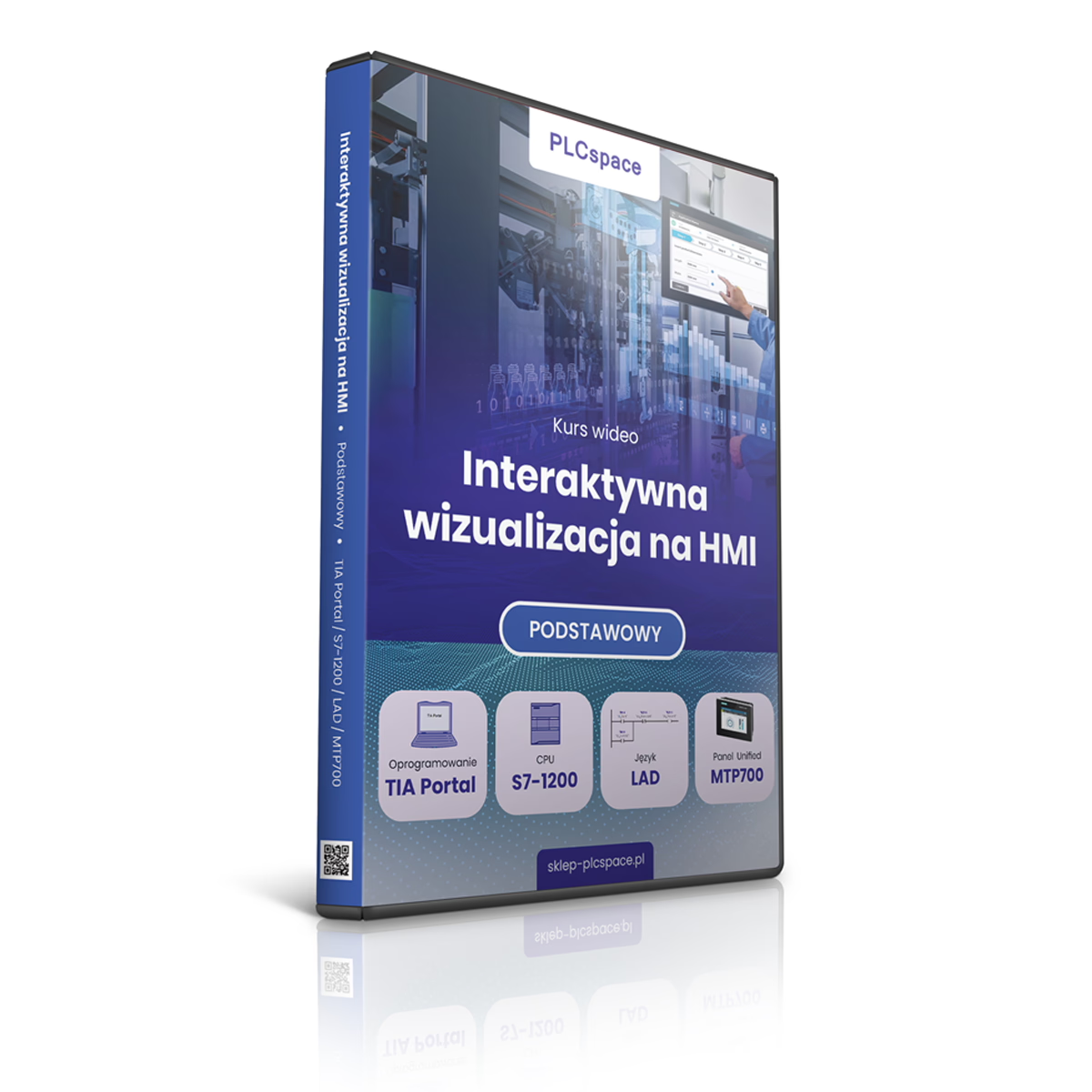

You may also be interested in:

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

274.57 € 182.97 €

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

111.98 € 11.22 €

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

0.00 €

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

22.67 € 18.09 €