I want to become a PLC programmer

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

399.00 zł – 499.00 zł

What do you get when you enrol on a PLC programming course?

Don't be afraid that we will charge you with complicated knowledge that you will find difficult to assimilate. Nothing could be further from the truth! The course is designed to familiarise you with the basics of PLC. As part of the training, you will receive carefully selected aids:

I want to become a PLC programmer. Siemens PLC programming course, basic level - TIA Portal software

Simatic PLCs are a staple in any industry where machine automation is used. This course is dedicated to a particularly important family of PLCs - the Simatic S7-1200. In your theoretical classes, you've surely heard that these are extremely flexible controllers that are ideal for handling both simple and complex projects.

Our PLC course will enable you to master the basics of programming Siemens controllers, even if you have not dealt with them before. You will gain practical knowledge that you will use in your daily work.

If you have a technical background and dream of working as an automation engineer but don't know how to get started, you've come to the right place! After our Simatic PLC programming course, you will surprise your employer with your knowledge and out-of-the-box approach.

What is the Siemens Simatic PLC programming course about?

Our PLC programming course is designed to explain the given topic to you from the very beginning to intermediate level. The topics we cover during the course will be useful in any profession where you will be exposed to industrial programming. If you want to learn how to program and supervise machines in a factory, knowing how to program Siemens Simatic PLC logic controllers will help you to better understand the relationships that occur between components.

This PLC training course focuses on one of Siemens' most popular controllers, the S7-1200. In combination with the TIA Portal software, it creates a very powerful development environment. It is now possible to operate the Siemens Simatic S7-1200 controller in up to three languages. Within the scope of our training, you will be introduced to the graphical programming language LAD, popularly known as Ladder. It is extremely accessible to beginners.

The course is taught using the Industry Line app, which will take you into a virtual factory. This will allow you to see how each machine is operated and easily combine theory and practice.

Programming Siemens S7-1200 PLCs is convenient because it does not require you to purchase any additional software or hardware. You will solve all your problems in the TIA Portal v. 14SP1 environment, which is just for controlling Siemens modules. You can download it for free from the manufacturer's website and the software will remain fully functional for 21 days. This is far more than you need to complete the PLC basic course.

Would you like to know that you do not need to wade through thick books written in a complicated language to learn about PLC programming in LAD? Tired of learning the theoretical basics of PLCs after which nothing stays in your head? Then choose our Siemens programming course?

Knowledge test:

Is this course for you? Take this test MULTIPLE choice to check it out.

Egzamin Summary

0 of 9 Questions completed

Questions:

Information

You have already completed the egzamin before. Hence you can not start it again.

Egzamin is loading…

You must sign in or sign up to start the egzamin.

You must first complete the following:

Results

Results

0 of 9 Questions answered correctly

Your time:

Time has elapsed

You have reached 0 of 0 point(s), (0)

Earned Point(s): 0 of 0, (0)

0 Essay(s) Pending (Possible Point(s): 0)

Categories

- Not categorized 0%

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- Current

- Review

- Answered

- Correct

- Incorrect

-

Question 1 of 9

1. Question

Do the interrupt blocks change the cycle time?

CorrectIncorrect -

Question 2 of 9

2. Question

In which languages can code be written for the S7-1200 PLC?

CorrectIncorrect -

Question 3 of 9

3. Question

What states (values) can the bit assume?

CorrectIncorrect -

Question 4 of 9

4. Question

Is "state 0" returned by

CorrectIncorrect -

Question 5 of 9

5. Question

How many bits does a BYTE type consist of?

CorrectIncorrect -

Question 6 of 9

6. Question

What is the result of a comparison operation?

CorrectIncorrect -

Question 7 of 9

7. Question

What type of memory is defined as ephemeral (loss of data after power failure) ?

CorrectIncorrect -

Question 8 of 9

8. Question

Which data types consist of 32 bits?

CorrectIncorrect -

Question 9 of 9

9. Question

What bytes are included in the address %ID0 ?

CorrectIncorrect

Key information about the course

You will find that you are eager to reach for complementary knowledge yourself. On our course, we don't just teach the theoretical basics of programming. We show you concrete solutions, tricks and tricks that PLC professionals use. Believe us that after this training, your employers will be surprised by the level you represent. We will teach you the analytical thinking that every PLC programmer should master.

Although the work of an automation programmer may be mainly associated with loneliness, in reality it is usually quite the opposite. PLC programmers become part of a team that works together on a single project. No worries! After our course, you will feel like a real professional, discussing the results of your work with managers, investors, teammates. We will show you how to choose optimal solutions that take into account the time and cost required to implement them.

You will also learn how to avoid them and work on your craft. Most PLC courses you will find on the web are limited to imparting theory. We offer you something more - concrete solutions to the pitfalls and problems that beginners encounter while helplessly spreading their hands. We explain how to avoid them and why this is so important.

The virtual factory will show you the typical challenges faced by automation professionals working in industry. You will master the stress of real work. With Factory I/O you will be able to test any solution that comes your way, without the risk of plant delays, breakdowns or causing accidents. With a secure development environment, you learn faster and stress-free.

With many years of working on large projects, we pass on the best programming practices that you will use in any job. You will meet many other programmers during your career and not all of them will represent a good school of programming. Our aim is to give you the knowledge and skills that distinguish the best. We're not just about teaching you how to program a PLC because that's what you read about in textbooks. By mastering good automation work practices, you will excel with diligence and a creative approach to problem solving.

Why choose our industrial automation course?

You will find many a Simatic PLC tutorial on the market, but our training is a whole different level. What can a really great course look like?

Sample lesson / What you will do after the course

What is the Simatic S7-1200 controller programming training in the TIA Portal environment?

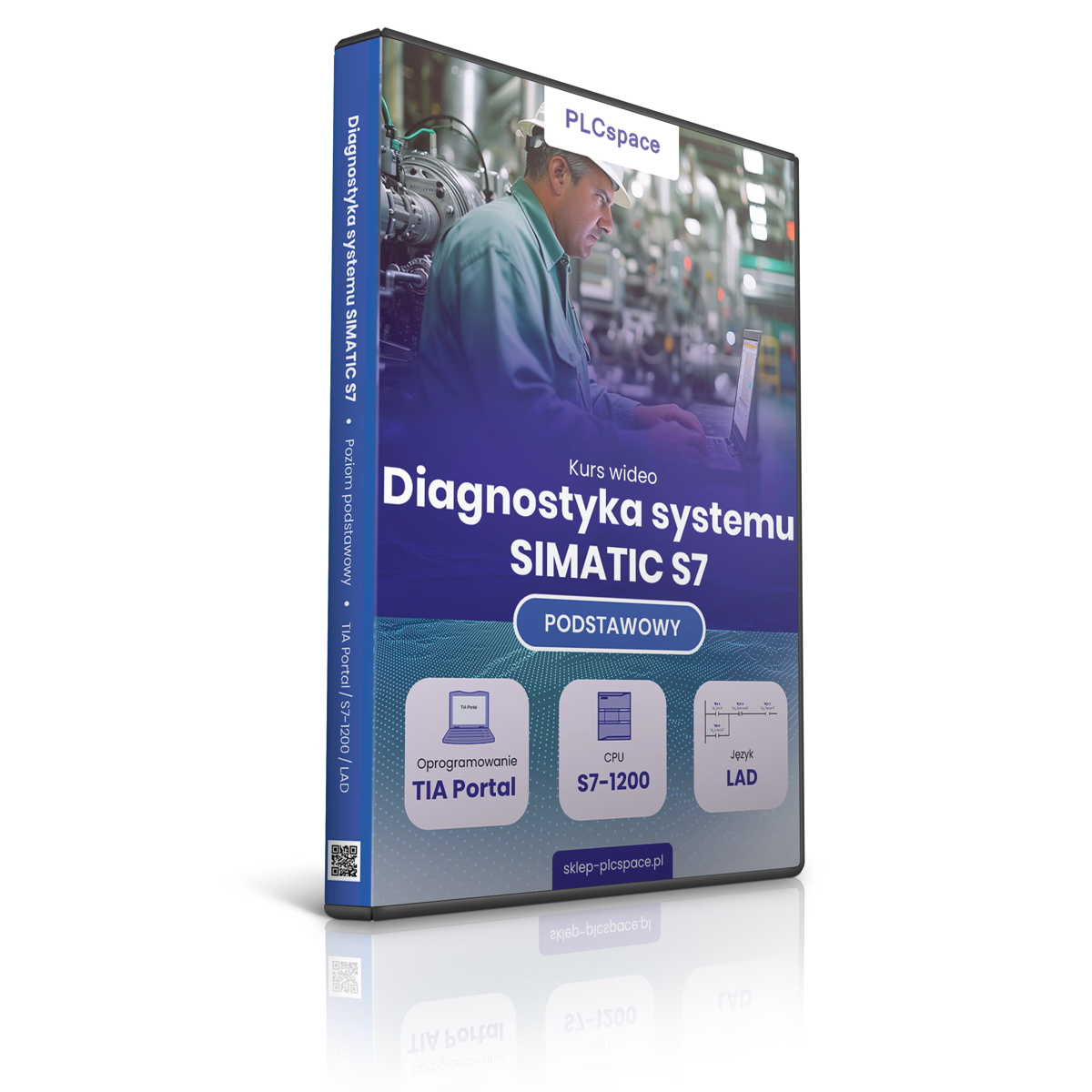

Our Siemens Simatic S7-1200 PLC training consists of 5 parts, each of which is dedicated to different blocks of topics. You will learn how to control PLC modules and use them in your daily work to improve the functioning of your project. What information will you find in each part?

After completing all modules, you will have a working knowledge of programming machine controllers that you can use in your everyday duties. Find out that PLCs can be easy to use. Check out the courses on offer today!

-

Module 1

- Installation of TIA Portal v13 SP2 - Windows 7

- Installation of TIA Portal v13 SP2 PLCSIM - Windows 7

- Installation of TIA Portal v14 SP1 - Windows 7

- Installation of TIA Portal v14 SP1 PLCSIM - Windows 7

-

Module 2

- Installation of TIA Portal v13 SP2 - Windows 10

- Installation of TIA Portal v14 SP1 - Windows 10

- Installation of TIA Portal v14 SP1 PLCSIM - Windows 10

-

Module 3

- TIA Portal v14 SP1 licence

-

Module 4

- PLC connection

-

Module 1 - System overview

- SIMATIC S7-1200 - for microautomation and beyond

- SIMATIC HMI Basic Panels - focusing on the basics

- TIA Portal - Integrated system for PLC and HMI

- Structure of control systems

- SIMATIC S7-1200 new modular PLC

- SIMATIC S7-1200 - CPU

- SIMATIC S7-1200 - Signal boards

- SIMATIC S7-1200 - Expansion modules

- SIMATIC S7-1200 - Expansion modules

- SIMATICS7-1200 - Accessories

- SIAMTIC S7-1200 - Working memory

- SIMATIC memory card

- Integrated PROFINET interface

- Point-to-point communication

- Integrated technology functions

- CPU Firmware system update new features

- Communication

- PROFINET I/O

- PROFIBUS DP

- Diagnostic functions

- Technological features

- System requirements

- SIMATIC S7-1200 Summary

-

Module 2 - TIA Portal

- TIA Portal - a modern engineering tool

- Portal view

- Project view

- Project editor - Project tree

- Project editor - Project window

- Project editor - Task sheets

- Project: Choice of language and storage location

- Editorial window navigation elements

- Working in several editorial windows

- Online tools

- Project record

- Help system: Instructions

- Help system navigation tools

- Licence

- Libraries

- Project libraries

- Global library

-

Module 3 - Device configuration and connection

- IP address of the PG/PC programming station

- Portal view: Facilities available

- Project view: Available equipment

- Standard CPU configuration

- Device and network configuration editor

- Device and network configuration editor - Functionality

- Equipment catalogue

- Storage of unconnected modules

- PLC characteristics: PROFINET interface

- PLC characteristics: Digital inputs

- PLC characteristics: Digital outputs

- PLC characteristics: Analogue inputs

- PLC characteristics: High-speed inputs(HSC)

- PLC characteristics: Start types

- PLC characteristics: Real-time clock

- PLC properties: Programme security

- PLC properties: System and clock byte

- Adding/deleting/replacing modules

- Signal board

- Network view - Device connection

- Compilation of hardware devices

-

Module 4 - Training kit

- S7-1200 Training set, addressing

- S7-1200 Training set, expansion modules

-

Module 5 - PLC variables

- PLC variables / local variables

- PLC variables "PLC tags"

- Creating a group of "PLC tags" variables

- Option to search for and modify "PLC tags" variables

- Sorting of variables in the "PLC tags" array

- Monitoring of the values of "PLC tags" variables

- PLC tags: Retained memory area

- PLC tags: properties of variables

- PLC tags: declaration errors

- Programme block editor: Show hide symbolic names

- Programme block editor: Addressing prompts

- Programme block editor: Renaming a variable

- Programme block editor: Changing the address of a variable

-

Module 6 - Programmable blocks

- PLC variables / local variables

- Types of blocks

- OB - Organisational block

- DB - Data Block

- FC - Functions

- FB - Function block

- DB - Instance data blocks

- DB - Multi-instance data block

- Programme structure

- Grouping of programme blocks

- Addition of a new programme block

- Features of the block

- Protection of block content

- Interface of variable declarations in the FB function

- Programming instructions

- Bar of frequently used instructions

- Posting of comments

- Expand/hide programme lines

- Selection of the type of variable for the instruction

- Block record

- Calling a block

- Function block parameters

- Block update

- Block compilation

- Program download to PLC

- Block monitoring

-

Module 7 - Logical operations

- Programming instructions

- Operations on bits: IF instruction

- Operations on bits: Assignment, Set, Reset

- Bit operations: RLO/signal edge detection

- Data transfer operations: MOVE_BLK

- Data transfer operations: UMOVE_BLK

- Mathematical operations: LIMIT, MOD

- Mathematical operations: MIN, MAX

- Logical operations: DECO, ENCO

- Logical operations: SEL, MUX

- Conversion operations: NORM_X, SCALE_X

- Data comparison operations: IN_RANGE, OUT_RANGE

- Date and time operations: RD_SYS_T

- String + Char operations: VAL_STRG

- Operations on counters: CTU

- Clock operations: TON

- Indirect addressing (FieldRead)

- Indirect addressing (FieldWrite)

-

Module 1 - Data blocks

- Data Blocks (DB)

- S7 data types

- Basic data types

- Complex data types: DTL

- Complex data types: ARRAY, STRUCT

- Creating data blocks: DB

- Editing and monitoring

- Memory optimisation

- Area of retained memory

- FB: Data support

- FB: Sustaining global memory

- DB multi instance : Memory backup

- DB: Symbolic/ absolute access

-

Module 2 - Organisational blocks

- Organisational Blocks (OB): Basics

- Organisational Blocks (OB): Properties

- OB block call events

- Interruption of a cyclic program (Interrupt)

- Cyclical Organisational Blocks (OB)

- Startup organisational blocks (Startup OB)

- Time delay interrupt support

- Cyclic interrupts

- Cyclic interrupts - time shift

- Hardware interrupts

- Activation of a hardware interrupt

- Hardware interrupts - Programme

- Calling/holding a hardware interrupt using the Attach/ detach function

- Activation of a diagnostic interrupt

- Equipment identifier (HW ID)

- Diagnostic interrupt handling block: OB82

- CPU cycle error handling block: OB 80

- Events that do not activate the OB. Interruption handling:

-

Module 1 - Programme diagnosis

- Online mode

- Switching the PLC between STOP and RUN mode

- Controller operating status

- Extension module diagnostics

- CPU diagnostic buffer

- Programme control: GetErrorID

- Online mode: Programme status

- Online mode: Block removal

- Monitoring of programme blocks

- Comparison of programme blocks

- Block comparison: Detailed comparison

- Watch tables

- Monitoring board: Trigger point

- Monitoring board: Modification of variables

- Monitoring board: Forcing variables

- Cross-reference list

- Block call location

- Call structure

- Call structure: Designations

- Assignment list" editor

- CPU memory "Resources"

-

Module 2 - Visualisation

- HMI panels - an introduction to families

- Device configuration

- Adding a device to the project

- HMI variables

- Visualisation screen editor

- Basic screen elements

- Addition of static text

- IO field - display of variables

- Uploading the configuration to the HMI

- Button object - link to variable

- Switching between screens

Software and hardware used

TIA Portal software

Totally integrated automation is a development environment that combines PLC (programming), HMI(visualisation) and startdrive(drive technology).

CPU S7-1200

The new controller, which has been developed as a successor to the S7-200, is characterised by slightly weaker parameters than the S7-300 family. Several CPU versions present in the family allow selection according to project requirements.

What will you be able to do after completing the course?

The effort you put into completing the course will undoubtedly pay off - knowledge of PLC programming will open the door to many jobs. Choose your specialisation according to what you most want to do

Learning based on dry theory is a relic. We offer you the chance to explore practical skills, something that really matters to employers. Our training will enable even someone with no programming experience to receive ready-made solutions that will help them find their way in the job market.

Guarantee

and certificate

If, after 14 days of purchase, you find that it is not for you, I will refund 100% of the course price. Upon completion of the course, you will receive a certificate in two languages - Polish and English.

Frequently asked questions

-

Will I receive a confirmation after my purchase?

Yes, you receive an email. Sometimes emails end up in SPAM or other folders. Please check your mailbox carefully.

-

Is there a difference between the media on which the course can be ordered?

No. The material is the same regardless of the type of storage medium. At the time of purchase, you decide which type of data carrier you choose, i.e. online, DVD or USB.

-

Which PLC programming language should I choose when starting out?

If you are an electrician then LAD. If there has been any exposure to text-based languages (C, C++, C#, Java, etc) then SCL. If there has been no exposure to any programming at all then the basic course is LAD and SCL (the solution to each task is shown in two languages).

-

Is this course for me if I have never used a PLC?

Yes. The basic courses are just set up so that people with no exposure to Siemens PLCs can learn such skills. The student is guided step by step (as can also be seen in the course table of contents).

-

What tools are used for consultation?

Consultations take place via Skype or TeamViever.

-

How do I make an appointment for a consultation?

Please send an email to biuro@plcspace.pl with your questions (problems) and suggestions for a convenient date for your consultation (via Skype or Teamviever).

-

How long are the consultations valid?

This is 60 calendar days from the date of purchase.

-

Can I deliver the course on different computers?

Yes. The course material (videos) can be viewed on any computer.

-

What does the online version of the course look like?

You receive the course by email, where there are private links to the videos.

-

What if a problem arises during the course?

Please email me with a description of the problem at: biuro@plcspace.pl.

-

What is the access time for the course?

No time limits for any medium (i.e. online, DVD or USB version).

-

Do I need to have any experience with programming?

No. The basic course gives step-by-step all the information needed from 'scratch'.

-

Will I need to purchase a licence for the Factory IO software?

No. There is information in the course on how to obtain licences to complete the material.

-

Will I need to purchase a licence for the PLC development environment?

No. There is information in the course on how to obtain licences to complete the material.

-

Is it possible to return the course?

Yes.

-

Will I need a PLC to deliver the course?

No. A real controller is not necessary. The course is designed in such a way that it can also be completed on a virtual controller. It all depends on what the trainee has at their disposal.

-

How do I buy a course?

Just click Add to basket and complete the form and make payment.

-

When does the course start?

-> Online version - immediately after payment

-> Physical version - when you receive the package from the carrier.

Buy as a set and save

Select at least 2 courses from the list and the first free book item (three selections in total) and an automatic discount of 25% will be calculated in your basket.

If you want to find out more about a particular course, click on its name and the page will take you to its offerings.

Companies that have benefited from our courses

Feedback from students

Stanislaw

Stanislaw

What sets this course apart is the opportunity to acquire practical, concrete knowledge. Everything is clearly explained. Definitely recommended!

Marcel

Marcel

After going through the course, I know what the components of the programming environment are and what to do step by step. Now I feel confident and know what I am doing

Leon

Leon

Course delivered in a very accessible way. Contains a lot of interesting and useful information.

Michael

Michael

I can honestly recommend the course. It is solid and factual knowledge. I will definitely be buying more.

Victor

Victor

Thanks to the course, I have decided to go further in this direction. The goal is to look for a more challenging and better job

Peter

Peter

The course prepared by Mr Tomasz is distinguished by its high level of content and meticulously prepared lessons. They are planned in a clear and sensible manner, making it easier to assimilate knowledge and return to the material if necessary. An additional advantage is the possibility of a free consultation.

Nikodem

Nikodem

Definitely recommended! The facts themselves, no unnecessary dwelling on issues.

Ignatius

Ignatius

This is my first course, certainly not my last. I am impressed with the substantive quality of the knowledge.

Tymon

Tymon

Everything clearly explained, you can really learn a lot. Lots of practical information and examples to help you remember everything. In my opinion, it is worth using this form of learning because you can learn anytime and anywhere. It is practical and convenient.

You may also be interested in:

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

499.00 zł 49.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

49.00 zł – 57.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

399.00 zł – 419.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

1.529.00 zł – 1.549.00 zł