MICROMASTER drive force

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

479.00 zł – 499.00 zł

What do you get when you enrol on the Micromaster family drive programming course?

When you decide to attend your first training course in propulsion technology, you may fear that you will be saddled with complex knowledge, and that this will be delivered in an indigestible way. Nothing could be further from the truth! The course is designed to familiarise you with the basics of PLC in the context of safety, so you will receive carefully selected teaching aids:

Basic course in drive engineering - TIA Portal software

The online drive automation training course will enable you to gain knowledge about the functioning of different types of motors and their individual components - asynchronous motors, braking modules, gearboxes, DU/DT filters, frequency converters and many other components. This is a universal course, after which you will learn the principles of the Micromaster family of drives with the Siemens Simatic S7-1200 controller.

Most industrial equipment uses various types of drives. You will find them in transmission belts or boom arms. However, for a motor to work, you need a converter. This is a special device or system that adjusts the process parameters to meet specific requirements.

No worries! We recommend our training to all beginners who plan to deal with automation but have no experience with issues such as electric drives, selection of drive accessories, contact elements or input chokes.

If you have acquired a technical education and dream of working as an automation technician, but don't know how to get started with PLCs and drives, you have come to the right place! After our course, terms such as gearmotor, ferrite rings, operating positions or operating factor will no longer be a mystery to you

What is the Fundamentals of Propulsion Technology course about?

The course programme focuses on the Micromaster 440 inverter for small applications. This drive family is distinguished by its compact and modular design, which is easy to adapt to the workstation. It also features convenient sensorless vector control.

However, that is not all. The device has a built-in braking transistor and a proportional-integral-differential controller, known as a PID. With its removable panel, the Micromaster 440 can be used with all types of frequency converters.

Our training in drive technology is dedicated to anyone wishing to explore the secrets of programming and optimising the operation of equipment such as machine tools, plastics processing lines or packaging machines. In all of these machines, the Micromaster 440 module and Siemens S7-1200 controllers are used most often. They are versatile and can be easily modified and adapted to handle a specific type of task.

In combination with TIA Portal, it creates a very powerful programming environment. Although it is now possible to program the Siemens Simatic S7-1200 in several languages, the training aims to introduce you to the graphical programming language LAD, popularly known as Ladder, as it resembles an electronic circuit diagram and is extremely accessible to beginners.

The TIA Portal software for training consists of two parts:

- Step 7 module for PLC programming;

- WinCC Comfort/Advanced module for creating visualisations.

The Micromaster Starter app will provide you with intuitive operation, whether you are just starting out with drive programming or have already taken your first steps into industrial programming.

Siemens S7-1200 PLC programming is convenient as it does not require you to purchase any additional software or hardware.

You will be solving all your problems in the TIA Portal v. 15.1 environment, which is just for controlling Siemens modules. You can download it for free from the manufacturer's website and the software will retain full functionality for 21 days. This is far more than you need to complete your PLC training. If you have older versions of the TIA Portal platform, you can also complete the entire training.

So, what, you want to find out that you don't have to wade through thick books written in a complicated language to acquire the knowledge of programming Safety PLCs in the LAD language? Do you want to learn how to create instructions for Siemens PLCs that are both efficient and safe? Here we go!

Knowledge test:

Is this course for you? Take this test MULTIPLE choice to check it out.

Key information about the course

With us you will learn about the practical application of the solutions discussed, we will reveal tricks, trivia and non-obvious applications of the PLCs discussed. You will be delighted to reach for more knowledge.

After this course, he or she will work efficiently on projects of varying scales in both small companies and large corporations that require a creative approach to problem solving.

You will learn how to work effectively and avoid mistakes, the more and less obvious ones.

In the hands of automation often rests the safety of the entire team. Check out the virtual factory app to see what you'll be up against and don't let obstacles defeat you at work.

There are many ways to program, but we only teach the effective, efficient and ethical ones. Learn about good programming practices with us.

Why choose this drive technology course in particular?

You'll find many a guide on the market for people wanting to explore driveline techniques, but our training is a whole different level. What can a really great course look like?

Sample lesson / What you will do after the course

What is the training like for those wishing to explore drive system parameterisation?

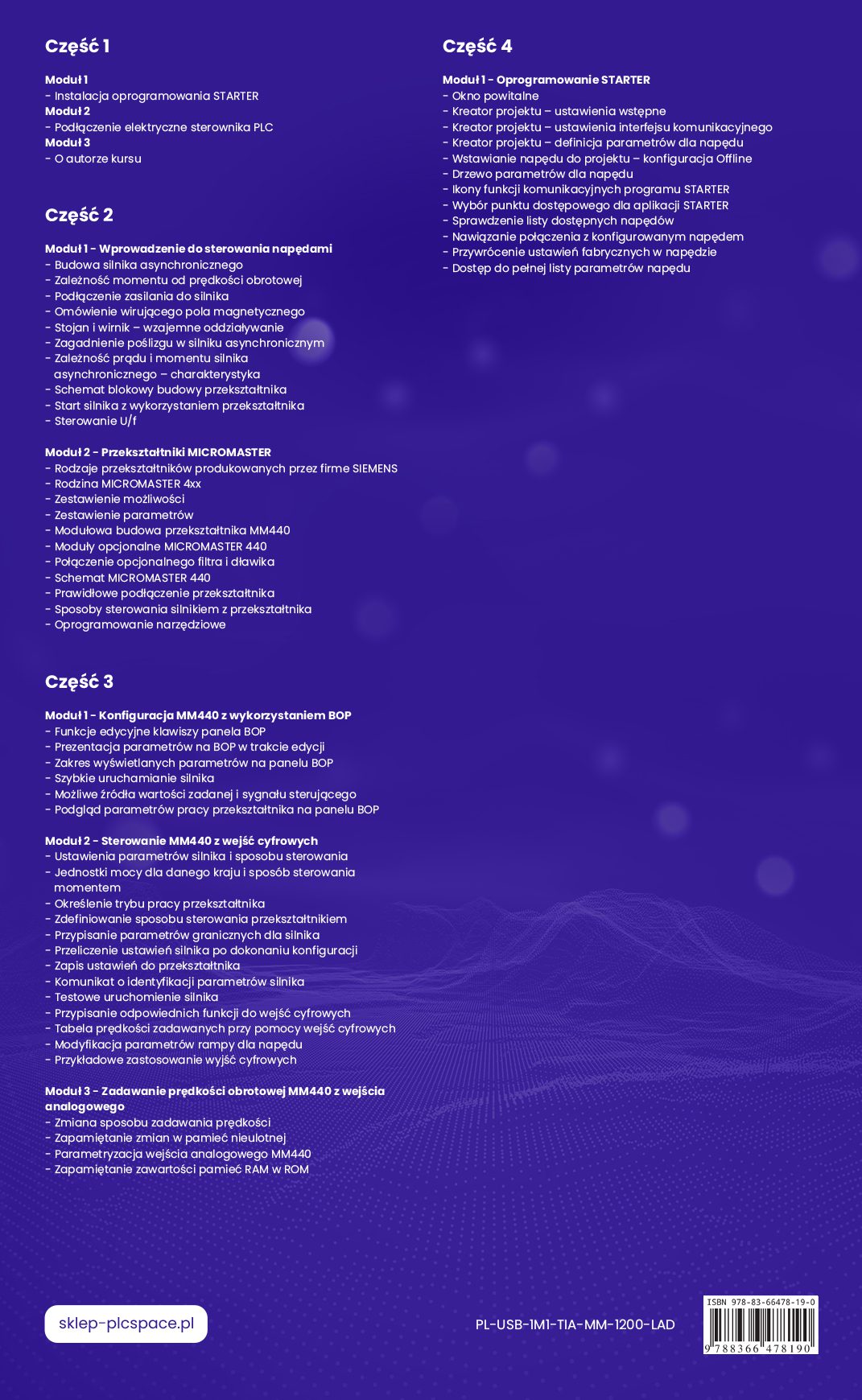

The training programme consists of four parts, each of which is dedicated to different blocks of issues. Once you have completed all of them, you will have safely and effectively programmed the drive modules and used them in your daily work to increase employee safety and improve plant operations.

Drive techniques are very important knowledge in the work of any automation technician and often underestimated in practice. Understanding it is essential for realising the full potential of PLCs. Start learning from the best and gain industry-critical practice.

Once you have completed all modules, you will have a working knowledge of Micromaster drive programming that you will use in your everyday duties. You will find that theoretical knowledge is not everything. Plan your career with PLCSpace training courses.

-

Module 1

- STARTER software installation

-

Module 2

- Electrical connection of the PLC

-

Module 3

- About the course author

-

Module 1 - Introduction to drive control

- Construction of the asynchronous motor

- Torque vs. speed relationship

- Connection of power supply to the motor

- Discussion of the rotating magnetic field

- Stator and rotor - mutual interaction

- The issue of slip in an asynchronous motor

- Current and torque relationship of the motor

asynchronous - characteristics - Block diagram of the converter design

- Motor start using a converter

- U/f control

-

Module 2 - MICROMASTER converters

- Types of converters manufactured by SIEMENS

- MICROMASTER 4xx family

- Summary of opportunities

- Summary of parameters

- Modular design of the MM440 converter

- Optional modules MICROMASTER 440

- Combination of optional filter and choke

- Diagram of MICROMASTER 440

- Correct connection of the converter

- Ways of controlling a motor from a converter

- Tool software

-

Module 1 - Configuring the MM440 using the BOP

- Editing functions of the BOP panel keys

- Presentation of parameters on the BOP during editing

- Range of displayed parameters on the BOP panel

- Quick engine start

- Possible sources of setpoint and control signal

- Viewing of converter operating parameters on the BOP panel

-

Module 2 - Control of the MM440 from digital inputs

- Motor parameter settings and control method

- Country-specific power units and control method

moment - Determining the operating mode of the converter

- Defining how to control the converter

- Assignment of motor limit parameters

- Recalculation of engine settings after configuration

- Writing settings to the converter

- Engine parameter identification message

- Test engine start-up

- Assignment of corresponding functions to the digital inputs

- Table of speeds set using digital inputs

- Modification of drive ramp parameters

- Example use of digital outputs

-

Module 3 - Speed reference MM440 from analogue input

- Changing the speed setting

- Storage of changes in non-volatile memory

- Parameterisation of the MM440 analogue input

- RAM storage in ROM

-

Module 1 - STARTER Software

- Welcome window

- Project wizard - pre-settings

- Project wizard - communication interface settings

- Project wizard - definition of drive parameters

- Inserting the drive into the project - Offline configuration

- Parameter tree for the drive

- STARTER communication function icons

- Selecting an access point for the STARTER application

- Checking the list of available drives

- Establishing a connection with the configured drive

- Resetting the drive to factory settings

- Access to a complete list of drive parameters

Software and hardware used

TIA Portal software

Totally integrated automation is a development environment that combines PLC (programming), HMI(visualisation) and startdrive(drive technology).

CPU S7-1200

The new controller, which has been developed as a successor to the S7-200, is characterised by slightly weaker parameters than the S7-300 family. Several CPU versions present in the family allow selection according to project requirements.

MICROMASTER drive

In the past, motor control was based on the on/off principle. This changed in the 1990s where infinitely variable control of the electric motor produced economical results.

What will you be able to do after completing the course?

Completing our course will enable you to find employment in a wide variety of industries. The practical knowledge you gain will make it easy for you to interest the employer of your choice in your services. Find out what you can do after the propulsion technology course.

Practical knowledge that is really important on the labour market cannot be learned at school. You won't get it from theoretical subjects and boring repetitions. Put your knowledge into practice, which is what employers value most. You don't need experience to become a specialist!

Guarantee

and certificate

If, after 14 days of purchase, you find that it is not for you, I will refund 100% of the course price. Upon completion of the course, you will receive a certificate in two languages - Polish and English.

Frequently asked questions

-

Will I receive a confirmation after my purchase?

Yes, you receive an email. Sometimes emails end up in SPAM or other folders. Please check your mailbox carefully.

-

Is there a difference between the media on which the course can be ordered?

No. The material is the same regardless of the type of storage medium. At the time of purchase, you decide which type of data carrier you choose, i.e. online, DVD or USB.

-

Which PLC programming language should I choose when starting out?

If you are an electrician then LAD. If there has been any exposure to text-based languages (C, C++, C#, Java, etc) then SCL. If there has been no exposure to any programming at all then the basic course is LAD and SCL (the solution to each task is shown in two languages).

-

Is this course for me if I have never used a PLC?

Yes. The basic courses are just set up so that people with no exposure to Siemens PLCs can learn such skills. The student is guided step by step (as can also be seen in the course table of contents).

-

What tools are used for consultation?

Consultations take place via Skype or TeamViever.

-

How do I make an appointment for a consultation?

Please send an email to biuro@plcspace.pl with your questions (problems) and suggestions for a convenient date for your consultation (via Skype or Teamviever).

-

How long are the consultations valid?

This is 60 calendar days from the date of purchase.

-

Can I deliver the course on different computers?

Yes. The course material (videos) can be viewed on any computer.

-

What does the online version of the course look like?

You receive the course by email, where there are private links to the videos.

-

What if a problem arises during the course?

Please email me with a description of the problem at: biuro@plcspace.pl.

-

What is the access time for the course?

No time limits for any medium (i.e. online, DVD or USB version).

-

Do I need to have any experience with programming?

No. The basic course gives step-by-step all the information needed from 'scratch'.

-

Will I need to purchase a licence for the Factory IO software?

No. There is information in the course on how to obtain licences to complete the material.

-

Will I need to purchase a licence for the PLC development environment?

No. There is information in the course on how to obtain licences to complete the material.

-

Is it possible to return the course?

Yes.

-

Will I need a PLC to deliver the course?

No. A real controller is not necessary. The course is designed in such a way that it can also be completed on a virtual controller. It all depends on what the trainee has at their disposal.

-

How do I buy a course?

Just click Add to basket and complete the form and make payment.

-

When does the course start?

-> Online version - immediately after payment

-> Physical version - when you receive the package from the carrier.

Buy as a set and save

Select at least 2 courses from the list and the first free book item (three selections in total) and an automatic discount of 25% will be calculated in your basket.

If you want to find out more about a particular course, click on its name and the page will take you to its offerings.

Companies that have benefited from our courses

Feedback from students

Stanislaw

Stanislaw

What sets this course apart is the opportunity to acquire practical, concrete knowledge. Everything is clearly explained. Definitely recommended!

Marcel

Marcel

After going through the course, I know what the components of the programming environment are and what to do step by step. Now I feel confident and know what I am doing

Leon

Leon

Course delivered in a very accessible way. Contains a lot of interesting and useful information.

Michael

Michael

I can honestly recommend the course. It is solid and factual knowledge. I will definitely be buying more.

Victor

Victor

Thanks to the course, I have decided to go further in this direction. The goal is to look for a more challenging and better job

Peter

Peter

The course prepared by Mr Tomasz is distinguished by its high level of content and meticulously prepared lessons. They are planned in a clear and sensible manner, making it easier to assimilate knowledge and return to the material if necessary. An additional advantage is the possibility of a free consultation.

Nikodem

Nikodem

Definitely recommended! The facts themselves, no unnecessary dwelling on issues.

Ignatius

Ignatius

This is my first course, certainly not my last. I am impressed with the substantive quality of the knowledge.

Tymon

Tymon

Everything clearly explained, you can really learn a lot. Lots of practical information and examples to help you remember everything. In my opinion, it is worth using this form of learning because you can learn anytime and anywhere. It is practical and convenient.

You may also be interested in:

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

399.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

39.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

39.00 zł

- Level:

The development environment used in the course

- Software:

Core unit family used in the course

- CPU:

A set of rules that are used to develop programme code

- Language:

Frequency converter (inverter) family used in the course

- Drive

1.824.00 zł